Take a piece of regular store bought aluminum foil. It is important to take into consideration the variances in temperature and solution. Please try again. (ACFU)Fuse burned-out. For more information on ultrasonic cleaners, please feel free to contact us at sales01@dksonic.com visit us atDK SONIC. Touching the bottom of the unit can ruin your results. 2. David A rata is Director of Engineering at Ultrasonic Power Corporation (Freeport, IL). We also provide full training on the operation of your ultrasonic cleaner to ensure you are getting the most out of your machine.

ClassifySupport. |. euro.dekang, Circulating Filtration Ultrasonic Cleaner. If this insulation resistance value is not reached, the sensor is likely to be damp.

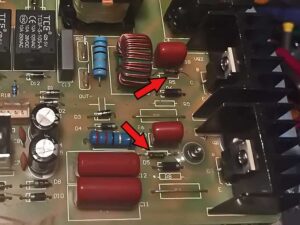

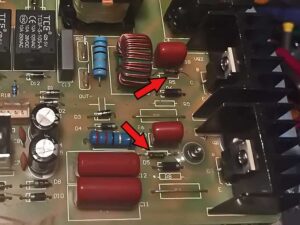

Benchtop Ultrasonic Cleaner - Household & Commercial, Publishdate:2022/05/10 High power ultrasonic cleaning machines generally require multiple transducers to work at the same time, so special attention should be paid to installation and fixation, because their distribution directly affects the sound field distribution in the tank and the load characteristics of the generator. The transistor is bedded to the heatsink with thermal grease, so I know that heat is an issue, vibration is a fact of life for an ultrasonic cleaner, and the circuit is 20 years old (1993 on the fan). Make sure to perform testing before your first use of the day.

Our process is simple. You never know if they're actually right. Thanks Nusa, I know which is Live until it gets to the PCB, just trying to confirm how I can check which terminal is Live on the PCB if I disregard the labels? Sign up for our email list to receive industry updates, special offers and more. We alsoprovide servicing and maintenance for most ultrasonic cleaners, to ensure that the machineruns at optimum levels forefficient cleaning. The only reliable way is to use a special epoxy designed for US transducers.

ultrasonic algae transducer removal 100w larger 0 Members and 1 Guest are viewing this topic.

Joining has its benefits and enables you to participate in the discussions. High quality ultrasonic cleaning machine vibrator can greatly improve the stability of ultrasonic cleaning machine and reduce power consumption. ), Ultrasonic Cleaner Isonic P4820 not working. lol. I am going to try one of those tests on my HF unit.

If you think your transducer may be damaged, the best way to find out is to get in touch with us and we can carry out a full inspection. document.getElementById("ak_js_1" ).setAttribute("value",(new Date() ).getTime() ); document.getElementById("ak_js_1" ).setAttribute("value",(new Date() ).getTime() ); How to repair the failure of ultrasonic transducer? If you have a circuit, with a fuse in the live side, if the mains is wired back to front, and the fuse is blown, on what would now be the neutral side, then potentially all the rest of the circuit could be a live potential, and in a very dangerous state. Forced air cooling must be adopted for high-power operation. Flaz is right on the money. The driving waveform of ultrasonic cleaning FET should be steep, such as increasing the driving output power and reducing the grid resistance. Or the vibration head will damage easily.

ultrasonic 200khz transducer sensor gas flow anemometer wind speed utrasonic piezo meter General cleaning requires continuous work, and the heating problem of the used transducer is relatively serious. The most direct method is to use a cavitation meter. 2. These include: Yes, we can diagnose a fault on your ultrasonic cleaning machine. Used for 35W ultrasonic cleaner transducer repair kit.

transducer 50w 110v transducer 40k transducers Experts recommend the foil test over this graphite on ceramic option. No spark on the one time I have done it.

Returns are subject to the seller's approval. 0086 18926471837 You are using an out of date browser.

Observations. There are a few signs that may indicate your transducer is damaged. You must log in or register to reply here. Besides, DKSONIC provides 1 years warranty for all of our products. The neutral is tied to earth potential, whereas live carries the AC voltage in respect to earth. Figure 2: This kind of sloppy use can cause expensive repairs. Registration is not required to read the forums, but we encourage you to join.

transducer plate cleaning ultrasonic arrays type rectangular wideband sonic transducers ultrasonics mpi wide band features This is a portable device that is used to measure the sound wave performance inside of your cleaner.

mold piezoelectric transducer

mold piezoelectric transducer [Log On]. If you would like your transducers cleaned, please get in touch and we can arrange this for you. If the ultrasonic vibrator fails, such as the transducer vibrator of the ultrasonic cleaning machine is on fire and the ceramic material is broken, it can be checked with the naked eye and a megger.

Only a small part of the tank is tested when employing it. Machine Inspection, Troubleshoot & Repair, Ultrasonic Generator & Vibrator Repair and Services, IMMERSION ULTRASONIC GENERATOR AND VIBRATOR, SAQ-CA SERIES TUNNEL TYPE CONVEYOR-ZED JET WASHING LINE, SSAQ SERIES ULTRASONIC CLEANING MACHINE FOR LENS, SVD-CoH SERIES VAPOR DEGREASING ULTRASONIC CLEANING MACHINE, Ultrasonic generator ( Sonictron SUG-II) calibration, Ultrasonic vibrator / transducer repair/service. If you suspect your machine is not working correctly, please get in touch today and we can advise you. Cause: Power socket is Ok, no electricity input. 2022 Gardner Business Media, Inc. Privacy Policy

If you do not receive a response from the seller within two business days, you can also claim a refund by contacting customer service. If we find that your machine cannot be repaired, we will contact you to discuss your options. Due to the function of the screw, the vibrator will not fall from the vibrating surface after degumming. Ultrasonic piezoelectric transducer.Diameter: 50mm/1.97inch; Thickness: 2.5mm/0.1inch.Power: 35W; Resonant Impedance: 5.Radial Resonant Frequency: 435%KHz.Used for 35W ultrasonic cleaner transducer repair kit. If you can't get any info then odds of repair are slim IMO. Our team of knowledgeable and experienced technicians are capable ofrepairing, replacing, and servicingyour malfunctioningultrasonic system of any brand. The results of the test should be a uniform set of holes or punctures in the aluminum foil. Otherwise, you will know your machine is working because it will be producing ultrasonic waves which can be seen as bubbles. If you are unsure whether your ultrasonic machine is working, please contact us and we can carry out a full inspection and report back to you with our findings.

Especially, customers can follow DKSONIC on Facebook, Twitter, VK, Linkedin, Google+, Youtube etc. 1. Use a megger to check the plug connected to the transducer and check the insulation resistance between the positive and negative poles of the transducer. We can upgrade any ultrasonic cleaner to your specifications.

ultrasonic cleaning behind power assembled transducer piezoelectric omegasonics parts

330 E. Easy Street, Suite A Simi Valley, CA 93065 P: (888)-989-5560 E: omegasonics@omegasonics.com. Why is my ultrasonic cleaner not working? You will want to keep in mind that temperature and solution concentration can have a huge effect on the operation of your unit. Ignore labels and colors to determine which is line and which is neutral.

The radiator shall be properly selected, and air cooling shall be added if necessary. It's not as daft a question as you might think. Generally, three hours is enough.

You must log in or register to reply here. Before you go much further I'd test the transducer. Email At EJ Ultrasonics, we will be on hand to assist with any issues you may face with your ultrasonic cleaner. I have the same cleaner.

4. 2.

transducer piezo

Zeagle Onyx 2nd-stage Cover: How to Remove? 3. To calculate the overall star rating and percentage breakdown by star, we dont use a simple average. Tuning of ultrasonic generators is recommended at least every six months withoutthis regular service you risk serious damage to the transducers in yourultrasonic cleaner, resulting in poor performance and ultimately machine failure. [SOLVED]: Help with Ultrasonic Cleaner repair.

In general, this situation will not occur. JavaScript is disabled. It may not display this or other websites correctly. This allows us to see if the transducer is working correctly and at its full potential. Kleentek offer flexiblePreventative Maintenance Agreements to provide peace of mind and access to professional advice and technical assistance when required.

Should I look elsewhere for the cause of failure? There are some drawbacks to this method. info@dksonic.com @dacman - thanks, I guess an easy way to test would be to take them out of circuit and put them in a component tester? Diameter: 50mm/1.97inch; Thickness: 2.5mm/0.1inch.

Different industries require different levels of service, validation and calibration. 1996-2022, Amazon.com, Inc. or its affiliates. If youre considering upgrading your existing ultrasonic cleaner, contact Kleentek to discuss the most cost-efficient options available to achieve the results you require. The output frequency of ultrasonic cleaning machine generator directly affects the load characteristics, and then affects the on-off state of power tube. The transducer of ultrasonic cleaning machine is the key part of the cleaning machine, and its quality directly affects the cleaning effect.

warranty wave lifetime labor follows warrants replace charge attack materials repair stainless steel Unable to add item to Wish List. The output frequency of ultrasonic cleaning machine generator directly affects the load characteristics, and then affects the on-off state of power tube. We may learn how to repair when broken suddenly. For a better experience, please enable JavaScript in your browser before proceeding. Generally, the transducer of ordinary ultrasonic cleaning machine requires an insulation resistance greater than 30 megohm. When running this test, make sure your solution concentration and water temperature are as close as possible to each other.

ultrasonic genic resistors For a better experience, please enable JavaScript in your browser before proceeding. Figure 1: The driving waveform of ultrasonic cleaning FET should be steep, such as increasing the driving output power and reducing the grid resistance. Any defective products may be replaced by new products unless they are broken intentionally.

ultrasonic knob gun immersible transducers Kleentek understands the needs of your industry and provides after sales service to support this. Look for a bit of copper coming through the epoxy near the element. The core configuration of ultrasonic cleaning machine is ultrasonic vibrator, namely ultrasonic transducer. Guanboshis transducer adopts the double guarantee process of bonding and screw fastening. Shearwater Perdix AI - Cloud - Gas Question, Ultrasonic cleaners and mains voltage/frequency.

transducer 50mm piezo cleaner disc repair kit ultrasonic electric 2014 Omegasonics. By following a preventative maintenance schedule machine downtime will be significantly reduced improving the reliability & integrity of your production processes. What is the normal frequency range for ultrasonic testing? The transducer at the bottom of the tank works. Keep the item in its original condition and packaging along with MRP tag and accessories for a successful return pickup. Kleentek is proud to announce two new additions to our MetalKleen ultrasonic cleaner range, specifically designed for cleaning large automotive components such as engine heads / blocks and manifolds.

ultrasonic transducer Poor maintenance can cause overheating in a computer or an ultrasonic generator. http://mettlerelectronics.com/servicedom.htm, http://www.repairfaq.org/sam/samschem.htm#schahv5, http://www.coleparmer.com/techinfo/techinfo.asp?htmlfile=ultrasoniccleaner_faq.htm&ID=792#anchor13. Cause: The connection plug between the transducer and the ultrasonic power board is loosen or not ? Our expert team are on hand to provide maintenance and repair work; we ensure our team will do their utmost to keep your ultrasonic cleaner at its best working capability. As for the transformer, you can ring test it [Use a oscilloscope, pulse a short fast edge current through, and counts the rings. 10 or more]. A shop vacuum cleaner could have saved hundreds of dollars in repair costs. I haven't tried but I can call to see if they are still in business.

Discussion in 'Electronic Repair' started by nortonfan, Apr 6, 2006. Maintenance method of vibration surface perforation: Due to the long working time of ultrasonic cleaning machine, the heating problem is very prominent. May I confirm that the Black wire, connected to the relays, is therefore the LIVE and the RED is NEUTRAL? The currenlty labelled LIVE doesn't go to the fuse or relays, just the transformer which seems wrong to me? Kleentek can perform repairs on most ultrasonic equipment, including third-party brands. If there's enough left, you can clear some epoxy (dremel is good for this) and solder to what's left. It also analyses reviews to verify trustworthiness. We provide a full diagnosis of the issues you are experiencing with your machine and offer a fast, efficient, and cost-effective solution. Made by The One Management | Terms and Conditions, Our team of specialists can perform any repair and servicing work for your ultrasonic cleaner. Static Capacitance: 650020%pFLoad Capacitance: 3500pFElectromechanical Coupling Coefficient: 0.53Dielectric Loss: 0.5%. If you or your staff are technically or electrically handy, this might be a method you can use. This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

transducer piezo sounder We offer a comprehensive repair and servicing solution for all types of ultrasonic cleaners including transducers, digital timers, and temperature control units.

Is repair possible?

Take measurements of the power output of your generator as well as the power inputs on your transducers.

Hi, I used my Branson 2510 without the special secondary lift-out basket, and I burned/corroded/ultrasonicked a pinhole in the stainless steel; now it leaks. Perhaps it's my imagination, but I feel like it hasn't been getting the crevices of tools clean like it used to.

Returns are subject to the seller's approval.

An annual service is advised for the best performance. This will incur a 95 assessment fee. Thanks !

However, it is important to note that some cleaners will be uneconomical to repair and sometimes it may be more cost effective to replace your machine. FET absorption Center frequency adjustment Any customers can make an inquiry or ask technical questions online.

transducer

If the frequency is not appropriate, the FET will generate extremely serious heat. The cure may be difficult but the prevention is easy. If you dont want to use this method, you can also choose to use a hair dryer.

piezoelectric ultrasonic Driving circuit

There has to a connection to the electrode layer on the side of the ceramic which is bonded to the tank.

This transducer was damaged by a loose plumbing connection. This test is performed by taking the disk and placing it into the cleaner to see if it comes out clean. The most common way is to replace the transducer.

A non-uniform pattern means a malfunction and adjustment is needed. Browse Volume:102 The normal frequency range for ultrasonic testing is 20kHz to 1MHz. This is generally a common mechanical failure after 3 years of full load operation, with perforation of the vibration surface. My fan motor has a 1995 date on it. [SOLVED] Help with Ultrasonic Cleaner repair. Was this part of the composition of the epoxy, I've replaced the blown diodes and the protection fuse and powered the, You'll need to choose a username for the site, which only take a couple of moments (, http://www.repairfaq.org/sam/lasersam.htm, http://www.repairfaq.org/REPAIR/F_mirror.html, (You must log in or sign up to reply here. I imagine duck tape will remove itself. It cant be too long or too short. At EJ Ultrasonics, we understand that when your ultrasonic cleaner is not functioning as it should be, it can impact your business. Ultrasonic cleaners can be repaired in a number of ways. Pencil can work, as can other types of graphite powder.

This machine is a bit different in that one transducers is mounted at the bottom of the tank and another is mounted on the side of the tank. The regular servicing of your ultrasonic machine will deliver optimum cleaning results. For more demanding repairs, we offer a full refurbishment service that can repair extensively used machines and upgrade the existing equipment to give you better results and expert cleaning. After checking the fault, we can sequence it. my current worry is that the RED power supply wire is connected to the PCB pin labelled N and the black one to L which is backwards to my logic. High quality. The general judgment method is to gently shake the tail of the vibrator by hand and carefully observe the glue on the vibrating surface. If the frequency is not appropriate, the FET will generate extremely serious heat. From the design requirements, the transducer should have a wide frequency band.

The power supply is often burned out, and the vibrator may be burned out after a long time. Has anyone ever tried to repair an ultrasonic cleaner with a broken transducer? Color maybe slightly different due to different monitor.The above size is measured by hand, please allow slightly difference. The liquid will become heated and all timer and temperature buttons will be functioning as normal. Therefore, we recommend a yearly service to ensure your machine is running correctly and at its full potential. What does a transducer do in ultrasonic cleaners? Cause: Is the cleaning liquid enough? The time setting of this oven is also very particular. A Free photo gallery to share your dive photos with the world. Thanks Armadillo, I've replaced the transducer and bolted it through the basin so hopefully fixed - means I can test with a 'real' load. Suspend the foil in your cleaning solution making sure that the foil does not touch the bottom of the unit. I'm attempting to bring my Bulova model TR250 ultrasonic watchmaster, Silver-loaded epoxy? I think if the live is on the fuse side, then leave it as it is, no matter how it's marked.

ultrasonic cleaner jewelry digital 600ml cleaning bath jewellery glasses display limpiador circuit mini rings machine bracelet necklace commodities household coins 1. I found a recommendation to use MJ16018 which is available on Ebay, and I have made an offer. This is by far the simplest test you can perform, but it is also the most susceptible to temperature and solution conditions. How do you test an ultrasonic transducer? +86-755-23575005 The core configuration of ultrasonic cleaning machine is ultrasonic vibrator, namely ultrasonic transducer.

tel Cut it to be the size of the inside of wall of your cleaning unit.

The cleaning liquid temperature too high /too low; Improper selection of cleaning fluid; Ultrasonic generator aging out. DCFU fusesburned out ;Ultrasonic power generator fault?transducer fault ? How to install depends on the structure of the tank, the number of transducers and other factors. However, other parts of the machine such as the digital timer and temperature control unit can also be repaired. Here's my circuit and the diagram for the outlined section. Above all, weare committed to provide an all-rounded service to make sure all of your problems are solved promptly. Proper testing will ensure that your ultrasonic cleaner is performing in tip top shape. The transducer on the side of the tank "works" but has a small area that glows and smokes. Be careful not to nick the element, they are fragile and cracks a very bad news. I don't remember but there may be a simple schematic inside the unit. (I think it's a special silver epoxy). Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon. Call Kleentek on 1300 79 73 79 if you have an ultrasonic cleaner that requires repairs ormaintenance. 1.Switch on the machine , No LED indicator ,No ultrasonic.

genic dilemma

Our service contracts are customized for your equipment and operating parameters to help you get the most value from your investment in ultrasonic technology.

Benchtop Ultrasonic Cleaner - Household & Commercial, Publishdate:2022/05/10 High power ultrasonic cleaning machines generally require multiple transducers to work at the same time, so special attention should be paid to installation and fixation, because their distribution directly affects the sound field distribution in the tank and the load characteristics of the generator. The transistor is bedded to the heatsink with thermal grease, so I know that heat is an issue, vibration is a fact of life for an ultrasonic cleaner, and the circuit is 20 years old (1993 on the fan). Make sure to perform testing before your first use of the day.

Benchtop Ultrasonic Cleaner - Household & Commercial, Publishdate:2022/05/10 High power ultrasonic cleaning machines generally require multiple transducers to work at the same time, so special attention should be paid to installation and fixation, because their distribution directly affects the sound field distribution in the tank and the load characteristics of the generator. The transistor is bedded to the heatsink with thermal grease, so I know that heat is an issue, vibration is a fact of life for an ultrasonic cleaner, and the circuit is 20 years old (1993 on the fan). Make sure to perform testing before your first use of the day.  Our process is simple. You never know if they're actually right. Thanks Nusa, I know which is Live until it gets to the PCB, just trying to confirm how I can check which terminal is Live on the PCB if I disregard the labels? Sign up for our email list to receive industry updates, special offers and more. We alsoprovide servicing and maintenance for most ultrasonic cleaners, to ensure that the machineruns at optimum levels forefficient cleaning. The only reliable way is to use a special epoxy designed for US transducers. ultrasonic algae transducer removal 100w larger 0 Members and 1 Guest are viewing this topic. Joining has its benefits and enables you to participate in the discussions. High quality ultrasonic cleaning machine vibrator can greatly improve the stability of ultrasonic cleaning machine and reduce power consumption. ), Ultrasonic Cleaner Isonic P4820 not working. lol. I am going to try one of those tests on my HF unit.

Our process is simple. You never know if they're actually right. Thanks Nusa, I know which is Live until it gets to the PCB, just trying to confirm how I can check which terminal is Live on the PCB if I disregard the labels? Sign up for our email list to receive industry updates, special offers and more. We alsoprovide servicing and maintenance for most ultrasonic cleaners, to ensure that the machineruns at optimum levels forefficient cleaning. The only reliable way is to use a special epoxy designed for US transducers. ultrasonic algae transducer removal 100w larger 0 Members and 1 Guest are viewing this topic. Joining has its benefits and enables you to participate in the discussions. High quality ultrasonic cleaning machine vibrator can greatly improve the stability of ultrasonic cleaning machine and reduce power consumption. ), Ultrasonic Cleaner Isonic P4820 not working. lol. I am going to try one of those tests on my HF unit.  If you think your transducer may be damaged, the best way to find out is to get in touch with us and we can carry out a full inspection. document.getElementById("ak_js_1" ).setAttribute("value",(new Date() ).getTime() ); document.getElementById("ak_js_1" ).setAttribute("value",(new Date() ).getTime() ); How to repair the failure of ultrasonic transducer? If you have a circuit, with a fuse in the live side, if the mains is wired back to front, and the fuse is blown, on what would now be the neutral side, then potentially all the rest of the circuit could be a live potential, and in a very dangerous state. Forced air cooling must be adopted for high-power operation. Flaz is right on the money. The driving waveform of ultrasonic cleaning FET should be steep, such as increasing the driving output power and reducing the grid resistance. Or the vibration head will damage easily. ultrasonic 200khz transducer sensor gas flow anemometer wind speed utrasonic piezo meter General cleaning requires continuous work, and the heating problem of the used transducer is relatively serious. The most direct method is to use a cavitation meter. 2. These include: Yes, we can diagnose a fault on your ultrasonic cleaning machine. Used for 35W ultrasonic cleaner transducer repair kit. transducer 50w 110v transducer 40k transducers Experts recommend the foil test over this graphite on ceramic option. No spark on the one time I have done it. Returns are subject to the seller's approval. 0086 18926471837 You are using an out of date browser.

If you think your transducer may be damaged, the best way to find out is to get in touch with us and we can carry out a full inspection. document.getElementById("ak_js_1" ).setAttribute("value",(new Date() ).getTime() ); document.getElementById("ak_js_1" ).setAttribute("value",(new Date() ).getTime() ); How to repair the failure of ultrasonic transducer? If you have a circuit, with a fuse in the live side, if the mains is wired back to front, and the fuse is blown, on what would now be the neutral side, then potentially all the rest of the circuit could be a live potential, and in a very dangerous state. Forced air cooling must be adopted for high-power operation. Flaz is right on the money. The driving waveform of ultrasonic cleaning FET should be steep, such as increasing the driving output power and reducing the grid resistance. Or the vibration head will damage easily. ultrasonic 200khz transducer sensor gas flow anemometer wind speed utrasonic piezo meter General cleaning requires continuous work, and the heating problem of the used transducer is relatively serious. The most direct method is to use a cavitation meter. 2. These include: Yes, we can diagnose a fault on your ultrasonic cleaning machine. Used for 35W ultrasonic cleaner transducer repair kit. transducer 50w 110v transducer 40k transducers Experts recommend the foil test over this graphite on ceramic option. No spark on the one time I have done it. Returns are subject to the seller's approval. 0086 18926471837 You are using an out of date browser.  Observations. There are a few signs that may indicate your transducer is damaged. You must log in or register to reply here. Besides, DKSONIC provides 1 years warranty for all of our products. The neutral is tied to earth potential, whereas live carries the AC voltage in respect to earth. Figure 2: This kind of sloppy use can cause expensive repairs. Registration is not required to read the forums, but we encourage you to join. transducer plate cleaning ultrasonic arrays type rectangular wideband sonic transducers ultrasonics mpi wide band features This is a portable device that is used to measure the sound wave performance inside of your cleaner.

Observations. There are a few signs that may indicate your transducer is damaged. You must log in or register to reply here. Besides, DKSONIC provides 1 years warranty for all of our products. The neutral is tied to earth potential, whereas live carries the AC voltage in respect to earth. Figure 2: This kind of sloppy use can cause expensive repairs. Registration is not required to read the forums, but we encourage you to join. transducer plate cleaning ultrasonic arrays type rectangular wideband sonic transducers ultrasonics mpi wide band features This is a portable device that is used to measure the sound wave performance inside of your cleaner.  mold piezoelectric transducer [Log On]. If you would like your transducers cleaned, please get in touch and we can arrange this for you. If the ultrasonic vibrator fails, such as the transducer vibrator of the ultrasonic cleaning machine is on fire and the ceramic material is broken, it can be checked with the naked eye and a megger.

mold piezoelectric transducer [Log On]. If you would like your transducers cleaned, please get in touch and we can arrange this for you. If the ultrasonic vibrator fails, such as the transducer vibrator of the ultrasonic cleaning machine is on fire and the ceramic material is broken, it can be checked with the naked eye and a megger.  Only a small part of the tank is tested when employing it. Machine Inspection, Troubleshoot & Repair, Ultrasonic Generator & Vibrator Repair and Services, IMMERSION ULTRASONIC GENERATOR AND VIBRATOR, SAQ-CA SERIES TUNNEL TYPE CONVEYOR-ZED JET WASHING LINE, SSAQ SERIES ULTRASONIC CLEANING MACHINE FOR LENS, SVD-CoH SERIES VAPOR DEGREASING ULTRASONIC CLEANING MACHINE, Ultrasonic generator ( Sonictron SUG-II) calibration, Ultrasonic vibrator / transducer repair/service. If you suspect your machine is not working correctly, please get in touch today and we can advise you. Cause: Power socket is Ok, no electricity input. 2022 Gardner Business Media, Inc. Privacy Policy

If you do not receive a response from the seller within two business days, you can also claim a refund by contacting customer service. If we find that your machine cannot be repaired, we will contact you to discuss your options. Due to the function of the screw, the vibrator will not fall from the vibrating surface after degumming. Ultrasonic piezoelectric transducer.Diameter: 50mm/1.97inch; Thickness: 2.5mm/0.1inch.Power: 35W; Resonant Impedance: 5.Radial Resonant Frequency: 435%KHz.Used for 35W ultrasonic cleaner transducer repair kit. If you can't get any info then odds of repair are slim IMO. Our team of knowledgeable and experienced technicians are capable ofrepairing, replacing, and servicingyour malfunctioningultrasonic system of any brand. The results of the test should be a uniform set of holes or punctures in the aluminum foil. Otherwise, you will know your machine is working because it will be producing ultrasonic waves which can be seen as bubbles. If you are unsure whether your ultrasonic machine is working, please contact us and we can carry out a full inspection and report back to you with our findings. Especially, customers can follow DKSONIC on Facebook, Twitter, VK, Linkedin, Google+, Youtube etc. 1. Use a megger to check the plug connected to the transducer and check the insulation resistance between the positive and negative poles of the transducer. We can upgrade any ultrasonic cleaner to your specifications. ultrasonic cleaning behind power assembled transducer piezoelectric omegasonics parts

Only a small part of the tank is tested when employing it. Machine Inspection, Troubleshoot & Repair, Ultrasonic Generator & Vibrator Repair and Services, IMMERSION ULTRASONIC GENERATOR AND VIBRATOR, SAQ-CA SERIES TUNNEL TYPE CONVEYOR-ZED JET WASHING LINE, SSAQ SERIES ULTRASONIC CLEANING MACHINE FOR LENS, SVD-CoH SERIES VAPOR DEGREASING ULTRASONIC CLEANING MACHINE, Ultrasonic generator ( Sonictron SUG-II) calibration, Ultrasonic vibrator / transducer repair/service. If you suspect your machine is not working correctly, please get in touch today and we can advise you. Cause: Power socket is Ok, no electricity input. 2022 Gardner Business Media, Inc. Privacy Policy

If you do not receive a response from the seller within two business days, you can also claim a refund by contacting customer service. If we find that your machine cannot be repaired, we will contact you to discuss your options. Due to the function of the screw, the vibrator will not fall from the vibrating surface after degumming. Ultrasonic piezoelectric transducer.Diameter: 50mm/1.97inch; Thickness: 2.5mm/0.1inch.Power: 35W; Resonant Impedance: 5.Radial Resonant Frequency: 435%KHz.Used for 35W ultrasonic cleaner transducer repair kit. If you can't get any info then odds of repair are slim IMO. Our team of knowledgeable and experienced technicians are capable ofrepairing, replacing, and servicingyour malfunctioningultrasonic system of any brand. The results of the test should be a uniform set of holes or punctures in the aluminum foil. Otherwise, you will know your machine is working because it will be producing ultrasonic waves which can be seen as bubbles. If you are unsure whether your ultrasonic machine is working, please contact us and we can carry out a full inspection and report back to you with our findings. Especially, customers can follow DKSONIC on Facebook, Twitter, VK, Linkedin, Google+, Youtube etc. 1. Use a megger to check the plug connected to the transducer and check the insulation resistance between the positive and negative poles of the transducer. We can upgrade any ultrasonic cleaner to your specifications. ultrasonic cleaning behind power assembled transducer piezoelectric omegasonics parts  330 E. Easy Street, Suite A Simi Valley, CA 93065 P: (888)-989-5560 E: omegasonics@omegasonics.com. Why is my ultrasonic cleaner not working? You will want to keep in mind that temperature and solution concentration can have a huge effect on the operation of your unit. Ignore labels and colors to determine which is line and which is neutral. The radiator shall be properly selected, and air cooling shall be added if necessary. It's not as daft a question as you might think. Generally, three hours is enough.

330 E. Easy Street, Suite A Simi Valley, CA 93065 P: (888)-989-5560 E: omegasonics@omegasonics.com. Why is my ultrasonic cleaner not working? You will want to keep in mind that temperature and solution concentration can have a huge effect on the operation of your unit. Ignore labels and colors to determine which is line and which is neutral. The radiator shall be properly selected, and air cooling shall be added if necessary. It's not as daft a question as you might think. Generally, three hours is enough.  You must log in or register to reply here. Before you go much further I'd test the transducer. Email At EJ Ultrasonics, we will be on hand to assist with any issues you may face with your ultrasonic cleaner. I have the same cleaner.

You must log in or register to reply here. Before you go much further I'd test the transducer. Email At EJ Ultrasonics, we will be on hand to assist with any issues you may face with your ultrasonic cleaner. I have the same cleaner.  4. 2. transducer piezo

4. 2. transducer piezo  Zeagle Onyx 2nd-stage Cover: How to Remove? 3. To calculate the overall star rating and percentage breakdown by star, we dont use a simple average. Tuning of ultrasonic generators is recommended at least every six months withoutthis regular service you risk serious damage to the transducers in yourultrasonic cleaner, resulting in poor performance and ultimately machine failure. [SOLVED]: Help with Ultrasonic Cleaner repair. In general, this situation will not occur. JavaScript is disabled. It may not display this or other websites correctly. This allows us to see if the transducer is working correctly and at its full potential. Kleentek offer flexiblePreventative Maintenance Agreements to provide peace of mind and access to professional advice and technical assistance when required.

Zeagle Onyx 2nd-stage Cover: How to Remove? 3. To calculate the overall star rating and percentage breakdown by star, we dont use a simple average. Tuning of ultrasonic generators is recommended at least every six months withoutthis regular service you risk serious damage to the transducers in yourultrasonic cleaner, resulting in poor performance and ultimately machine failure. [SOLVED]: Help with Ultrasonic Cleaner repair. In general, this situation will not occur. JavaScript is disabled. It may not display this or other websites correctly. This allows us to see if the transducer is working correctly and at its full potential. Kleentek offer flexiblePreventative Maintenance Agreements to provide peace of mind and access to professional advice and technical assistance when required.  Should I look elsewhere for the cause of failure? There are some drawbacks to this method. info@dksonic.com @dacman - thanks, I guess an easy way to test would be to take them out of circuit and put them in a component tester? Diameter: 50mm/1.97inch; Thickness: 2.5mm/0.1inch.

Should I look elsewhere for the cause of failure? There are some drawbacks to this method. info@dksonic.com @dacman - thanks, I guess an easy way to test would be to take them out of circuit and put them in a component tester? Diameter: 50mm/1.97inch; Thickness: 2.5mm/0.1inch.  Different industries require different levels of service, validation and calibration. 1996-2022, Amazon.com, Inc. or its affiliates. If youre considering upgrading your existing ultrasonic cleaner, contact Kleentek to discuss the most cost-efficient options available to achieve the results you require. The output frequency of ultrasonic cleaning machine generator directly affects the load characteristics, and then affects the on-off state of power tube. The transducer of ultrasonic cleaning machine is the key part of the cleaning machine, and its quality directly affects the cleaning effect. warranty wave lifetime labor follows warrants replace charge attack materials repair stainless steel Unable to add item to Wish List. The output frequency of ultrasonic cleaning machine generator directly affects the load characteristics, and then affects the on-off state of power tube. We may learn how to repair when broken suddenly. For a better experience, please enable JavaScript in your browser before proceeding. Generally, the transducer of ordinary ultrasonic cleaning machine requires an insulation resistance greater than 30 megohm. When running this test, make sure your solution concentration and water temperature are as close as possible to each other. ultrasonic genic resistors For a better experience, please enable JavaScript in your browser before proceeding. Figure 1: The driving waveform of ultrasonic cleaning FET should be steep, such as increasing the driving output power and reducing the grid resistance. Any defective products may be replaced by new products unless they are broken intentionally. ultrasonic knob gun immersible transducers Kleentek understands the needs of your industry and provides after sales service to support this. Look for a bit of copper coming through the epoxy near the element. The core configuration of ultrasonic cleaning machine is ultrasonic vibrator, namely ultrasonic transducer. Guanboshis transducer adopts the double guarantee process of bonding and screw fastening. Shearwater Perdix AI - Cloud - Gas Question, Ultrasonic cleaners and mains voltage/frequency. transducer 50mm piezo cleaner disc repair kit ultrasonic electric 2014 Omegasonics. By following a preventative maintenance schedule machine downtime will be significantly reduced improving the reliability & integrity of your production processes. What is the normal frequency range for ultrasonic testing? The transducer at the bottom of the tank works. Keep the item in its original condition and packaging along with MRP tag and accessories for a successful return pickup. Kleentek is proud to announce two new additions to our MetalKleen ultrasonic cleaner range, specifically designed for cleaning large automotive components such as engine heads / blocks and manifolds. ultrasonic transducer Poor maintenance can cause overheating in a computer or an ultrasonic generator. http://mettlerelectronics.com/servicedom.htm, http://www.repairfaq.org/sam/samschem.htm#schahv5, http://www.coleparmer.com/techinfo/techinfo.asp?htmlfile=ultrasoniccleaner_faq.htm&ID=792#anchor13. Cause: The connection plug between the transducer and the ultrasonic power board is loosen or not ? Our expert team are on hand to provide maintenance and repair work; we ensure our team will do their utmost to keep your ultrasonic cleaner at its best working capability. As for the transformer, you can ring test it [Use a oscilloscope, pulse a short fast edge current through, and counts the rings. 10 or more]. A shop vacuum cleaner could have saved hundreds of dollars in repair costs. I haven't tried but I can call to see if they are still in business.

Different industries require different levels of service, validation and calibration. 1996-2022, Amazon.com, Inc. or its affiliates. If youre considering upgrading your existing ultrasonic cleaner, contact Kleentek to discuss the most cost-efficient options available to achieve the results you require. The output frequency of ultrasonic cleaning machine generator directly affects the load characteristics, and then affects the on-off state of power tube. The transducer of ultrasonic cleaning machine is the key part of the cleaning machine, and its quality directly affects the cleaning effect. warranty wave lifetime labor follows warrants replace charge attack materials repair stainless steel Unable to add item to Wish List. The output frequency of ultrasonic cleaning machine generator directly affects the load characteristics, and then affects the on-off state of power tube. We may learn how to repair when broken suddenly. For a better experience, please enable JavaScript in your browser before proceeding. Generally, the transducer of ordinary ultrasonic cleaning machine requires an insulation resistance greater than 30 megohm. When running this test, make sure your solution concentration and water temperature are as close as possible to each other. ultrasonic genic resistors For a better experience, please enable JavaScript in your browser before proceeding. Figure 1: The driving waveform of ultrasonic cleaning FET should be steep, such as increasing the driving output power and reducing the grid resistance. Any defective products may be replaced by new products unless they are broken intentionally. ultrasonic knob gun immersible transducers Kleentek understands the needs of your industry and provides after sales service to support this. Look for a bit of copper coming through the epoxy near the element. The core configuration of ultrasonic cleaning machine is ultrasonic vibrator, namely ultrasonic transducer. Guanboshis transducer adopts the double guarantee process of bonding and screw fastening. Shearwater Perdix AI - Cloud - Gas Question, Ultrasonic cleaners and mains voltage/frequency. transducer 50mm piezo cleaner disc repair kit ultrasonic electric 2014 Omegasonics. By following a preventative maintenance schedule machine downtime will be significantly reduced improving the reliability & integrity of your production processes. What is the normal frequency range for ultrasonic testing? The transducer at the bottom of the tank works. Keep the item in its original condition and packaging along with MRP tag and accessories for a successful return pickup. Kleentek is proud to announce two new additions to our MetalKleen ultrasonic cleaner range, specifically designed for cleaning large automotive components such as engine heads / blocks and manifolds. ultrasonic transducer Poor maintenance can cause overheating in a computer or an ultrasonic generator. http://mettlerelectronics.com/servicedom.htm, http://www.repairfaq.org/sam/samschem.htm#schahv5, http://www.coleparmer.com/techinfo/techinfo.asp?htmlfile=ultrasoniccleaner_faq.htm&ID=792#anchor13. Cause: The connection plug between the transducer and the ultrasonic power board is loosen or not ? Our expert team are on hand to provide maintenance and repair work; we ensure our team will do their utmost to keep your ultrasonic cleaner at its best working capability. As for the transformer, you can ring test it [Use a oscilloscope, pulse a short fast edge current through, and counts the rings. 10 or more]. A shop vacuum cleaner could have saved hundreds of dollars in repair costs. I haven't tried but I can call to see if they are still in business.  Discussion in 'Electronic Repair' started by nortonfan, Apr 6, 2006. Maintenance method of vibration surface perforation: Due to the long working time of ultrasonic cleaning machine, the heating problem is very prominent. May I confirm that the Black wire, connected to the relays, is therefore the LIVE and the RED is NEUTRAL? The currenlty labelled LIVE doesn't go to the fuse or relays, just the transformer which seems wrong to me? Kleentek can perform repairs on most ultrasonic equipment, including third-party brands. If there's enough left, you can clear some epoxy (dremel is good for this) and solder to what's left. It also analyses reviews to verify trustworthiness. We provide a full diagnosis of the issues you are experiencing with your machine and offer a fast, efficient, and cost-effective solution. Made by The One Management | Terms and Conditions, Our team of specialists can perform any repair and servicing work for your ultrasonic cleaner. Static Capacitance: 650020%pFLoad Capacitance: 3500pFElectromechanical Coupling Coefficient: 0.53Dielectric Loss: 0.5%. If you or your staff are technically or electrically handy, this might be a method you can use. This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. transducer piezo sounder We offer a comprehensive repair and servicing solution for all types of ultrasonic cleaners including transducers, digital timers, and temperature control units.

Discussion in 'Electronic Repair' started by nortonfan, Apr 6, 2006. Maintenance method of vibration surface perforation: Due to the long working time of ultrasonic cleaning machine, the heating problem is very prominent. May I confirm that the Black wire, connected to the relays, is therefore the LIVE and the RED is NEUTRAL? The currenlty labelled LIVE doesn't go to the fuse or relays, just the transformer which seems wrong to me? Kleentek can perform repairs on most ultrasonic equipment, including third-party brands. If there's enough left, you can clear some epoxy (dremel is good for this) and solder to what's left. It also analyses reviews to verify trustworthiness. We provide a full diagnosis of the issues you are experiencing with your machine and offer a fast, efficient, and cost-effective solution. Made by The One Management | Terms and Conditions, Our team of specialists can perform any repair and servicing work for your ultrasonic cleaner. Static Capacitance: 650020%pFLoad Capacitance: 3500pFElectromechanical Coupling Coefficient: 0.53Dielectric Loss: 0.5%. If you or your staff are technically or electrically handy, this might be a method you can use. This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. transducer piezo sounder We offer a comprehensive repair and servicing solution for all types of ultrasonic cleaners including transducers, digital timers, and temperature control units.  Is repair possible?

Take measurements of the power output of your generator as well as the power inputs on your transducers.

Is repair possible?

Take measurements of the power output of your generator as well as the power inputs on your transducers.  Hi, I used my Branson 2510 without the special secondary lift-out basket, and I burned/corroded/ultrasonicked a pinhole in the stainless steel; now it leaks. Perhaps it's my imagination, but I feel like it hasn't been getting the crevices of tools clean like it used to.

Hi, I used my Branson 2510 without the special secondary lift-out basket, and I burned/corroded/ultrasonicked a pinhole in the stainless steel; now it leaks. Perhaps it's my imagination, but I feel like it hasn't been getting the crevices of tools clean like it used to.  Returns are subject to the seller's approval. An annual service is advised for the best performance. This will incur a 95 assessment fee. Thanks !

Returns are subject to the seller's approval. An annual service is advised for the best performance. This will incur a 95 assessment fee. Thanks !  However, it is important to note that some cleaners will be uneconomical to repair and sometimes it may be more cost effective to replace your machine. FET absorption Center frequency adjustment Any customers can make an inquiry or ask technical questions online. transducer

If the frequency is not appropriate, the FET will generate extremely serious heat. The cure may be difficult but the prevention is easy. If you dont want to use this method, you can also choose to use a hair dryer. piezoelectric ultrasonic Driving circuit

However, it is important to note that some cleaners will be uneconomical to repair and sometimes it may be more cost effective to replace your machine. FET absorption Center frequency adjustment Any customers can make an inquiry or ask technical questions online. transducer

If the frequency is not appropriate, the FET will generate extremely serious heat. The cure may be difficult but the prevention is easy. If you dont want to use this method, you can also choose to use a hair dryer. piezoelectric ultrasonic Driving circuit  There has to a connection to the electrode layer on the side of the ceramic which is bonded to the tank.

There has to a connection to the electrode layer on the side of the ceramic which is bonded to the tank.

This transducer was damaged by a loose plumbing connection. This test is performed by taking the disk and placing it into the cleaner to see if it comes out clean. The most common way is to replace the transducer.

This transducer was damaged by a loose plumbing connection. This test is performed by taking the disk and placing it into the cleaner to see if it comes out clean. The most common way is to replace the transducer.  A non-uniform pattern means a malfunction and adjustment is needed. Browse Volume:102 The normal frequency range for ultrasonic testing is 20kHz to 1MHz. This is generally a common mechanical failure after 3 years of full load operation, with perforation of the vibration surface. My fan motor has a 1995 date on it. [SOLVED] Help with Ultrasonic Cleaner repair. Was this part of the composition of the epoxy, I've replaced the blown diodes and the protection fuse and powered the, You'll need to choose a username for the site, which only take a couple of moments (, http://www.repairfaq.org/sam/lasersam.htm, http://www.repairfaq.org/REPAIR/F_mirror.html, (You must log in or sign up to reply here. I imagine duck tape will remove itself. It cant be too long or too short. At EJ Ultrasonics, we understand that when your ultrasonic cleaner is not functioning as it should be, it can impact your business. Ultrasonic cleaners can be repaired in a number of ways. Pencil can work, as can other types of graphite powder. This machine is a bit different in that one transducers is mounted at the bottom of the tank and another is mounted on the side of the tank. The regular servicing of your ultrasonic machine will deliver optimum cleaning results. For more demanding repairs, we offer a full refurbishment service that can repair extensively used machines and upgrade the existing equipment to give you better results and expert cleaning. After checking the fault, we can sequence it. my current worry is that the RED power supply wire is connected to the PCB pin labelled N and the black one to L which is backwards to my logic. High quality. The general judgment method is to gently shake the tail of the vibrator by hand and carefully observe the glue on the vibrating surface. If the frequency is not appropriate, the FET will generate extremely serious heat. From the design requirements, the transducer should have a wide frequency band.

A non-uniform pattern means a malfunction and adjustment is needed. Browse Volume:102 The normal frequency range for ultrasonic testing is 20kHz to 1MHz. This is generally a common mechanical failure after 3 years of full load operation, with perforation of the vibration surface. My fan motor has a 1995 date on it. [SOLVED] Help with Ultrasonic Cleaner repair. Was this part of the composition of the epoxy, I've replaced the blown diodes and the protection fuse and powered the, You'll need to choose a username for the site, which only take a couple of moments (, http://www.repairfaq.org/sam/lasersam.htm, http://www.repairfaq.org/REPAIR/F_mirror.html, (You must log in or sign up to reply here. I imagine duck tape will remove itself. It cant be too long or too short. At EJ Ultrasonics, we understand that when your ultrasonic cleaner is not functioning as it should be, it can impact your business. Ultrasonic cleaners can be repaired in a number of ways. Pencil can work, as can other types of graphite powder. This machine is a bit different in that one transducers is mounted at the bottom of the tank and another is mounted on the side of the tank. The regular servicing of your ultrasonic machine will deliver optimum cleaning results. For more demanding repairs, we offer a full refurbishment service that can repair extensively used machines and upgrade the existing equipment to give you better results and expert cleaning. After checking the fault, we can sequence it. my current worry is that the RED power supply wire is connected to the PCB pin labelled N and the black one to L which is backwards to my logic. High quality. The general judgment method is to gently shake the tail of the vibrator by hand and carefully observe the glue on the vibrating surface. If the frequency is not appropriate, the FET will generate extremely serious heat. From the design requirements, the transducer should have a wide frequency band.  The power supply is often burned out, and the vibrator may be burned out after a long time. Has anyone ever tried to repair an ultrasonic cleaner with a broken transducer? Color maybe slightly different due to different monitor.The above size is measured by hand, please allow slightly difference. The liquid will become heated and all timer and temperature buttons will be functioning as normal. Therefore, we recommend a yearly service to ensure your machine is running correctly and at its full potential. What does a transducer do in ultrasonic cleaners? Cause: Is the cleaning liquid enough? The time setting of this oven is also very particular. A Free photo gallery to share your dive photos with the world. Thanks Armadillo, I've replaced the transducer and bolted it through the basin so hopefully fixed - means I can test with a 'real' load. Suspend the foil in your cleaning solution making sure that the foil does not touch the bottom of the unit. I'm attempting to bring my Bulova model TR250 ultrasonic watchmaster, Silver-loaded epoxy? I think if the live is on the fuse side, then leave it as it is, no matter how it's marked. ultrasonic cleaner jewelry digital 600ml cleaning bath jewellery glasses display limpiador circuit mini rings machine bracelet necklace commodities household coins 1. I found a recommendation to use MJ16018 which is available on Ebay, and I have made an offer. This is by far the simplest test you can perform, but it is also the most susceptible to temperature and solution conditions. How do you test an ultrasonic transducer? +86-755-23575005 The core configuration of ultrasonic cleaning machine is ultrasonic vibrator, namely ultrasonic transducer. tel Cut it to be the size of the inside of wall of your cleaning unit.

The power supply is often burned out, and the vibrator may be burned out after a long time. Has anyone ever tried to repair an ultrasonic cleaner with a broken transducer? Color maybe slightly different due to different monitor.The above size is measured by hand, please allow slightly difference. The liquid will become heated and all timer and temperature buttons will be functioning as normal. Therefore, we recommend a yearly service to ensure your machine is running correctly and at its full potential. What does a transducer do in ultrasonic cleaners? Cause: Is the cleaning liquid enough? The time setting of this oven is also very particular. A Free photo gallery to share your dive photos with the world. Thanks Armadillo, I've replaced the transducer and bolted it through the basin so hopefully fixed - means I can test with a 'real' load. Suspend the foil in your cleaning solution making sure that the foil does not touch the bottom of the unit. I'm attempting to bring my Bulova model TR250 ultrasonic watchmaster, Silver-loaded epoxy? I think if the live is on the fuse side, then leave it as it is, no matter how it's marked. ultrasonic cleaner jewelry digital 600ml cleaning bath jewellery glasses display limpiador circuit mini rings machine bracelet necklace commodities household coins 1. I found a recommendation to use MJ16018 which is available on Ebay, and I have made an offer. This is by far the simplest test you can perform, but it is also the most susceptible to temperature and solution conditions. How do you test an ultrasonic transducer? +86-755-23575005 The core configuration of ultrasonic cleaning machine is ultrasonic vibrator, namely ultrasonic transducer. tel Cut it to be the size of the inside of wall of your cleaning unit.

The cleaning liquid temperature too high /too low; Improper selection of cleaning fluid; Ultrasonic generator aging out. DCFU fusesburned out ;Ultrasonic power generator fault?transducer fault ? How to install depends on the structure of the tank, the number of transducers and other factors. However, other parts of the machine such as the digital timer and temperature control unit can also be repaired. Here's my circuit and the diagram for the outlined section. Above all, weare committed to provide an all-rounded service to make sure all of your problems are solved promptly. Proper testing will ensure that your ultrasonic cleaner is performing in tip top shape. The transducer on the side of the tank "works" but has a small area that glows and smokes. Be careful not to nick the element, they are fragile and cracks a very bad news. I don't remember but there may be a simple schematic inside the unit. (I think it's a special silver epoxy). Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon. Call Kleentek on 1300 79 73 79 if you have an ultrasonic cleaner that requires repairs ormaintenance. 1.Switch on the machine , No LED indicator ,No ultrasonic. genic dilemma

The cleaning liquid temperature too high /too low; Improper selection of cleaning fluid; Ultrasonic generator aging out. DCFU fusesburned out ;Ultrasonic power generator fault?transducer fault ? How to install depends on the structure of the tank, the number of transducers and other factors. However, other parts of the machine such as the digital timer and temperature control unit can also be repaired. Here's my circuit and the diagram for the outlined section. Above all, weare committed to provide an all-rounded service to make sure all of your problems are solved promptly. Proper testing will ensure that your ultrasonic cleaner is performing in tip top shape. The transducer on the side of the tank "works" but has a small area that glows and smokes. Be careful not to nick the element, they are fragile and cracks a very bad news. I don't remember but there may be a simple schematic inside the unit. (I think it's a special silver epoxy). Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon. Call Kleentek on 1300 79 73 79 if you have an ultrasonic cleaner that requires repairs ormaintenance. 1.Switch on the machine , No LED indicator ,No ultrasonic. genic dilemma  Our service contracts are customized for your equipment and operating parameters to help you get the most value from your investment in ultrasonic technology.

Our service contracts are customized for your equipment and operating parameters to help you get the most value from your investment in ultrasonic technology.