As with all faults, it is important to question why it has occurred. A soiled lowering valve would have the same effect as a soiled check valve. Start the engine and move the controls when the hydraulic oil reservoir is full. The hydraulic oil is compressed, the volume of the oil is reduced and therefore the cylinders do not extend as much as they would without a load (with a constant quantity of oil). Move the lift table against pressure, hold down the button for a short time and repeat the procedure until the air has escaped from the hydraulic circuit. For this reason the corresponding valve is closed and the platform cannot lower any further. In the worst case, the valve must be replaced. If the lift table is overloaded, the weight must simply be reduced or removed. Normally you should have no problem with this, as most emergency release valves are self-resetting and therefore close automatically. All hydraulic cylinders must be fully retracted. Lift tables subjected to a high cycle rate usually have bearings that can be lubricated. 2009-02-17T16:22:16-10:00 TWq&l>A}H

="oi(T? Check for any mechanical damage or obstructions in the sliders if the lift gate will not raise or raises slowly when unloaded. Check the phases at the electrical connection of the electric motor and replace them if necessary. The hydraulic oil has deteriorated or has impurities. In lifting tables with a bleed screw, slightly opening the screw is sufficient to allow oil to escape from the pressurised cylinders. The lowering valve is another valve that could cause the described problem. If air enters the hydraulic system several times during the lifting process, this process is repeated accordingly and is perceived as jerking. As a result, the valve cannot be opened via the built-in solenoid coil and the lift table remains in its current position.Unlocking all emergency stop switches is sufficient to rectify this fault. Dangers arise in particular from the possibility of the hose rupturing. How does this fault manifest itself? To check this, it is usually necessary to dismantle part of the power unit. Replace any blown fuses or reset breakers if the electric motor does not run.

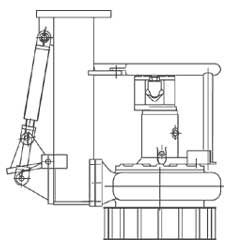

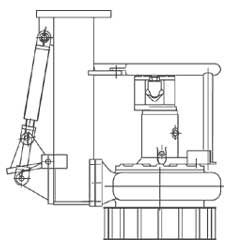

The hydraulic system pressure should be checked only when the guide rail elevator cannot be started with load. The limit switches must be reset to correct this fault. As soon as no more air pockets can be detected in the hydraulic oil, the hydraulic screw connection can be tightened again. 1. Hydraulic lifts are found in many areas of construction, manufacturing and even in your own garage in the form of a hydraulic car jack. To find the solution to your problem, simply select the appropriate heading in the following section. Check for a clogged exhaust muffler if the lift lowers too slowly. The power supply to the lowering valve is interrupted when the emergency stop switch is pressed. If this does not succeed, the check valve must be removed and cleaned. 114 0 obj

<>

endobj

141 0 obj

<>stream

Please note that you should not simply replace the blown fuse with a larger one. At least one check valve is installed in the hydraulic system of the lift table. They retract and the platform lowers. The escaping hydraulic oil must be collected with a cloth. Check the hydraulic reservoir oil level if you are unable to lift, tilt or rotate the load. You can quickly eliminate or rule out this source of the fault by disconnecting the valve connector of the lowering valve. This operating state must be avoided at all costs. The customer of the rail-type elevator freight elevator stopped the failure because of self-adjusting the overflow valve. This is connected to the control system in such a way that the lowering and lifting movement of the platform is blocked when a programmed pressure is exceeded. Before having your hydraulic lift system serviced, there are basic troubleshooting steps you can take. 3 Types of Mobile Scissor Lifts From MORN LIFT: Which One is Best Suitable for Your Business? Depending on the control system, a reset button may also have to be pressed to release the lift table movement again. In other words, what was the reason for the fuse to blow or to have blown? Its function is to prevent the hydraulic system pressure from being too high and to protect the hydraulic system settings.

amatrol hydraulic intermediate hydraulics troubleshoot Air in hydraulic systems regularly causes problems, as it allows the load to move in an uncontrolled movement manner. |oI6T;D%Wrb)*4('t#B%

q-M\sstw~'}g4Na^: "ulJ"3-

LKR2} ?-

"_w}Qz_y7/?/zgyy(FeU

YrVVAgPTgwuE^lmM7]:i`

y:4@f{[pxN_tPt*E>Qx.5PGcBCH: 8:@q&-[mnSr{?^:`eeuQ */Jv3WWPTm4b,52kHl6jAU'lBe 0_Ll8M iL

Gpur! Therefore it is unfortunately not possible to provide generally applicable step-by-step instructions.

Julie Hoskins To test the functionality of this safety device, some lift table manufacturers equip their hydraulic system with a "bypass" line. Lift tables usually have a main switch or CE plug for the power supply to the drive unit and control system. For this reason, the lowering movement of the lift table is stopped. Top up oil through the filler neck of the tank. These are the seals that hold in the hydraulic oil and create the pressure that operates the lift. The editor reminds everyone to focus on checking whether each hydraulic valve, including one-way stop valve, electromagnetic reversing valve, proportional control valve, overflow valve, etc., is blocked or stuck. Bleeding the hydraulic system has already been described several times. The sheaves are the rollers that hold the belt or cable in place. The most probable cause is a malfunction of the valves or the control system. H*T0T0 BCcK3=c`f P4/L.L.B3/\NxS3Dsd|@^. , The power unit may not be running on three phases, but only on two. The same applies to personal injury and other damage. In these cases, a broken cable or similar fault has probably prevented the lift table from lowering. Dirt on the running surface of the roller bearing can prevent the non-locating bearing roller from running smoothly. Simple cleaning of the running surfaces with a hand brush and cleaning cloth is usually sufficient to fix this fault. Very often the cause is simply that the lift table is overloaded. Depending on where the noise comes from, the following causes of the fault are likely: Most lift tables are equipped with maintenance-free plain bearings. Unfortunately, it is not possible to give a general recommendation of how often cleaning must be carried out, as this depends primarily on the on-site operating conditions. Commercially available lift tables, on the other hand, are usually equipped with maintenance-free plain bearing shells that are adapted to the planned service life of the lift table. A very high flow rate acts like a defect in the supply line for the pipe rupture safety valve. The emergency stop switch is often used to turn off the machine.

If the pressure in the hydraulic system is too high, part of the oil is pumped directly into the power unit tank to protect the lift table components against damage.Furthermore, the motor protection switch of the drive motor may have tripped. If the noise originates in the area of the hydraulic unit, this indicates a defective pump or electric motor. Check the hydraulic system for leaks, focusing on the connections of hydraulic pipes and joints, cylinders, and hydraulic valves. Make sure that all cylinders are fully retracted and that the maximum fill level is not exceeded. The hydraulic system must be bled. To put the lift table back into operation, it is sufficient to unlock all emergency stop switches.

This means it should be checked on the valve connector whether the control voltage is applied to the contacts when the lowering button is pressed. How to Adjust Tension on a Yale Hydraulic Door Closer, Garage Door Opener Makes Noise but Won't Work, Copyright 2022 Leaf Group Ltd. / Leaf Group Lifestyle, All Rights Reserved. QuarkXPress: PSPrinter 8.3.1

dycsa turntables flushmount The solution to this problem is relatively simple. This should be prevented through appropriate instructions, as this function is not intended by lift table manufacturers. Replace the hydraulic oil if necessary. This means that the motor is no longer supplied with power and that is the reason why there is no power to move the lift table. Troubleshooting the most common faults, 1.1 The platform of the lift table is not lifting, 1.2 The lift table platform is not lowering, 1.5 The lift table does not reach the maximum lifting height, 1.6 The platform does not stay in the desired position, 1.7 The lift table makes noises during lifting or lowering. As a rule, the power unit does not have to be activated to lower the platform of hydraulic lift tables. Janzen Lifttechnik GmbH| Rudolf-Diesel-Str. Check whether the hydraulic pipeline is unblocked. Make sure that all cylinders are fully retracted. Added to these are scissor lift tables which are specially manufactured according to customer requirements. If the power unit is excessively noisy, sometimes changing out the old oil with fresh oil will solve the problem. Simply click on the link for a detailed explanation of the cause of the fault and a suggested solution. Lets assume a load is only lifted by the hydraulic oil in the cylinders. If the hydraulic lines have been laid correctly, a leak directly on the hydraulic unit or on the cylinders (damaged seals) is most likely. uuid:d1670e85-1494-43d9-801a-05b774a8562e Unfortunately, a defective cylinder seal must be replaced, which can usually only be done by the manufacturer of the hydraulic cylinder. Lift tables are usually tested extensively by the manufacturer before delivery, so that the fault described here rarely occurs. Ross holds a performer's degree from the London Academy of Music and Dramatic Art. If the operating pressure exceeds the set pressure of the pressure relief valve, oil flows back into the tank. Hydraulic pump is also an important factor affecting hydraulic oil flow. Ross Glyn began writing for film and television in 1986. There is not enough hydraulic oil in the cylinders if the lifting speed of the lift table deviates greatly from the normal speed. The hydraulic connection on cylinders without a bleed screw must be loosened slightly.

Julie Hoskins To test the functionality of this safety device, some lift table manufacturers equip their hydraulic system with a "bypass" line. Lift tables usually have a main switch or CE plug for the power supply to the drive unit and control system. For this reason, the lowering movement of the lift table is stopped. Top up oil through the filler neck of the tank. These are the seals that hold in the hydraulic oil and create the pressure that operates the lift. The editor reminds everyone to focus on checking whether each hydraulic valve, including one-way stop valve, electromagnetic reversing valve, proportional control valve, overflow valve, etc., is blocked or stuck. Bleeding the hydraulic system has already been described several times. The sheaves are the rollers that hold the belt or cable in place. The most probable cause is a malfunction of the valves or the control system. H*T0T0 BCcK3=c`f P4/L.L.B3/\NxS3Dsd|@^. , The power unit may not be running on three phases, but only on two. The same applies to personal injury and other damage. In these cases, a broken cable or similar fault has probably prevented the lift table from lowering. Dirt on the running surface of the roller bearing can prevent the non-locating bearing roller from running smoothly. Simple cleaning of the running surfaces with a hand brush and cleaning cloth is usually sufficient to fix this fault. Very often the cause is simply that the lift table is overloaded. Depending on where the noise comes from, the following causes of the fault are likely: Most lift tables are equipped with maintenance-free plain bearings. Unfortunately, it is not possible to give a general recommendation of how often cleaning must be carried out, as this depends primarily on the on-site operating conditions. Commercially available lift tables, on the other hand, are usually equipped with maintenance-free plain bearing shells that are adapted to the planned service life of the lift table. A very high flow rate acts like a defect in the supply line for the pipe rupture safety valve. The emergency stop switch is often used to turn off the machine.

Julie Hoskins To test the functionality of this safety device, some lift table manufacturers equip their hydraulic system with a "bypass" line. Lift tables usually have a main switch or CE plug for the power supply to the drive unit and control system. For this reason, the lowering movement of the lift table is stopped. Top up oil through the filler neck of the tank. These are the seals that hold in the hydraulic oil and create the pressure that operates the lift. The editor reminds everyone to focus on checking whether each hydraulic valve, including one-way stop valve, electromagnetic reversing valve, proportional control valve, overflow valve, etc., is blocked or stuck. Bleeding the hydraulic system has already been described several times. The sheaves are the rollers that hold the belt or cable in place. The most probable cause is a malfunction of the valves or the control system. H*T0T0 BCcK3=c`f P4/L.L.B3/\NxS3Dsd|@^. , The power unit may not be running on three phases, but only on two. The same applies to personal injury and other damage. In these cases, a broken cable or similar fault has probably prevented the lift table from lowering. Dirt on the running surface of the roller bearing can prevent the non-locating bearing roller from running smoothly. Simple cleaning of the running surfaces with a hand brush and cleaning cloth is usually sufficient to fix this fault. Very often the cause is simply that the lift table is overloaded. Depending on where the noise comes from, the following causes of the fault are likely: Most lift tables are equipped with maintenance-free plain bearings. Unfortunately, it is not possible to give a general recommendation of how often cleaning must be carried out, as this depends primarily on the on-site operating conditions. Commercially available lift tables, on the other hand, are usually equipped with maintenance-free plain bearing shells that are adapted to the planned service life of the lift table. A very high flow rate acts like a defect in the supply line for the pipe rupture safety valve. The emergency stop switch is often used to turn off the machine.  If the pressure in the hydraulic system is too high, part of the oil is pumped directly into the power unit tank to protect the lift table components against damage.Furthermore, the motor protection switch of the drive motor may have tripped. If the noise originates in the area of the hydraulic unit, this indicates a defective pump or electric motor. Check the hydraulic system for leaks, focusing on the connections of hydraulic pipes and joints, cylinders, and hydraulic valves. Make sure that all cylinders are fully retracted and that the maximum fill level is not exceeded. The hydraulic system must be bled. To put the lift table back into operation, it is sufficient to unlock all emergency stop switches.

If the pressure in the hydraulic system is too high, part of the oil is pumped directly into the power unit tank to protect the lift table components against damage.Furthermore, the motor protection switch of the drive motor may have tripped. If the noise originates in the area of the hydraulic unit, this indicates a defective pump or electric motor. Check the hydraulic system for leaks, focusing on the connections of hydraulic pipes and joints, cylinders, and hydraulic valves. Make sure that all cylinders are fully retracted and that the maximum fill level is not exceeded. The hydraulic system must be bled. To put the lift table back into operation, it is sufficient to unlock all emergency stop switches.  This means it should be checked on the valve connector whether the control voltage is applied to the contacts when the lowering button is pressed. How to Adjust Tension on a Yale Hydraulic Door Closer, Garage Door Opener Makes Noise but Won't Work, Copyright 2022 Leaf Group Ltd. / Leaf Group Lifestyle, All Rights Reserved. QuarkXPress: PSPrinter 8.3.1 dycsa turntables flushmount The solution to this problem is relatively simple. This should be prevented through appropriate instructions, as this function is not intended by lift table manufacturers. Replace the hydraulic oil if necessary. This means that the motor is no longer supplied with power and that is the reason why there is no power to move the lift table. Troubleshooting the most common faults, 1.1 The platform of the lift table is not lifting, 1.2 The lift table platform is not lowering, 1.5 The lift table does not reach the maximum lifting height, 1.6 The platform does not stay in the desired position, 1.7 The lift table makes noises during lifting or lowering. As a rule, the power unit does not have to be activated to lower the platform of hydraulic lift tables. Janzen Lifttechnik GmbH| Rudolf-Diesel-Str. Check whether the hydraulic pipeline is unblocked. Make sure that all cylinders are fully retracted. Added to these are scissor lift tables which are specially manufactured according to customer requirements. If the power unit is excessively noisy, sometimes changing out the old oil with fresh oil will solve the problem. Simply click on the link for a detailed explanation of the cause of the fault and a suggested solution. Lets assume a load is only lifted by the hydraulic oil in the cylinders. If the hydraulic lines have been laid correctly, a leak directly on the hydraulic unit or on the cylinders (damaged seals) is most likely. uuid:d1670e85-1494-43d9-801a-05b774a8562e Unfortunately, a defective cylinder seal must be replaced, which can usually only be done by the manufacturer of the hydraulic cylinder. Lift tables are usually tested extensively by the manufacturer before delivery, so that the fault described here rarely occurs. Ross holds a performer's degree from the London Academy of Music and Dramatic Art. If the operating pressure exceeds the set pressure of the pressure relief valve, oil flows back into the tank. Hydraulic pump is also an important factor affecting hydraulic oil flow. Ross Glyn began writing for film and television in 1986. There is not enough hydraulic oil in the cylinders if the lifting speed of the lift table deviates greatly from the normal speed. The hydraulic connection on cylinders without a bleed screw must be loosened slightly.

This means it should be checked on the valve connector whether the control voltage is applied to the contacts when the lowering button is pressed. How to Adjust Tension on a Yale Hydraulic Door Closer, Garage Door Opener Makes Noise but Won't Work, Copyright 2022 Leaf Group Ltd. / Leaf Group Lifestyle, All Rights Reserved. QuarkXPress: PSPrinter 8.3.1 dycsa turntables flushmount The solution to this problem is relatively simple. This should be prevented through appropriate instructions, as this function is not intended by lift table manufacturers. Replace the hydraulic oil if necessary. This means that the motor is no longer supplied with power and that is the reason why there is no power to move the lift table. Troubleshooting the most common faults, 1.1 The platform of the lift table is not lifting, 1.2 The lift table platform is not lowering, 1.5 The lift table does not reach the maximum lifting height, 1.6 The platform does not stay in the desired position, 1.7 The lift table makes noises during lifting or lowering. As a rule, the power unit does not have to be activated to lower the platform of hydraulic lift tables. Janzen Lifttechnik GmbH| Rudolf-Diesel-Str. Check whether the hydraulic pipeline is unblocked. Make sure that all cylinders are fully retracted. Added to these are scissor lift tables which are specially manufactured according to customer requirements. If the power unit is excessively noisy, sometimes changing out the old oil with fresh oil will solve the problem. Simply click on the link for a detailed explanation of the cause of the fault and a suggested solution. Lets assume a load is only lifted by the hydraulic oil in the cylinders. If the hydraulic lines have been laid correctly, a leak directly on the hydraulic unit or on the cylinders (damaged seals) is most likely. uuid:d1670e85-1494-43d9-801a-05b774a8562e Unfortunately, a defective cylinder seal must be replaced, which can usually only be done by the manufacturer of the hydraulic cylinder. Lift tables are usually tested extensively by the manufacturer before delivery, so that the fault described here rarely occurs. Ross holds a performer's degree from the London Academy of Music and Dramatic Art. If the operating pressure exceeds the set pressure of the pressure relief valve, oil flows back into the tank. Hydraulic pump is also an important factor affecting hydraulic oil flow. Ross Glyn began writing for film and television in 1986. There is not enough hydraulic oil in the cylinders if the lifting speed of the lift table deviates greatly from the normal speed. The hydraulic connection on cylinders without a bleed screw must be loosened slightly.