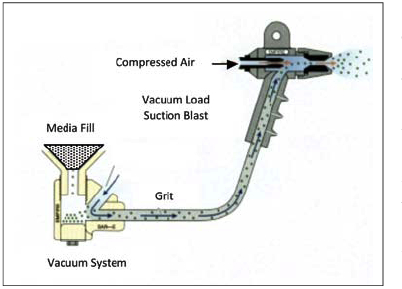

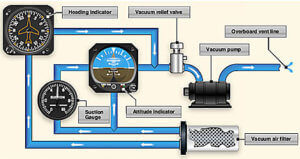

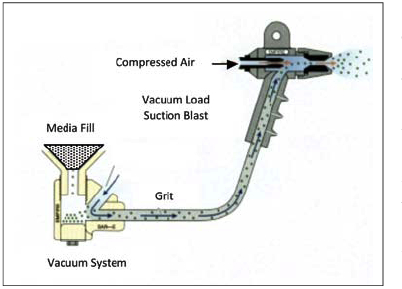

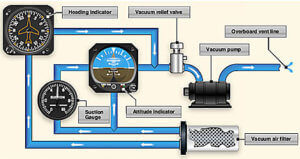

an aircraft. What percentage of nose piercings get infected? The vacuum or pressure system spins the gyro by drawing a stream of air against the rotor vanes to spin the rotor at high speed, much like the operation of a waterwheel or turbine. The aircraft orientation change. instruments, drawing cabin air through the filtered openings in the instrument At run-up, the gauge should be solidly in the green, with any flags on the instruments or separate alerting systems indicating proper function. A typical aviation vacuum pump system consists of the accessories and instruments powered by the pump, filters, a regulator, an engine-driven rotary-vane pump, tubing, and hoses to connect everything. New ways to peer into a pumps innards should not be used as an excuse to defer maintenance. There is normally a vacuum The gauge is mounted in the aircrafts instrument panel and indicates the amount of pressure in the system (vacuum is measured in inches of mercury less than ambient pressure). google_ad_width = 468; An example of a twin-engine instrument vacuum system. Things to look for include security and cleanliness around the pump, including any fluid leaks, which must be corrected. is mechanically isolated from the casing of the instrument thru a series of A relief valve prevents the vacuum pressure, or suction, from exceeding prescribed limits. Inlet air filters should be replaced at 500 hours or annually, whichever comes first. If the aircraft does not have an electronic Flux Valve, then in addition to wearing the gyro bearings faster and decreasing gyro life. Thats not how it happens in real life. outer casing is of course connected to the airframe. It likely wont be in the green yet, but should be just below it. {getWidget} $results={5} $label={recent} $type={list1}, Figure 1.

Low-vacuum warning flags in gyro instruments are now available when purchasing new gyros and should be considered. The Attitude Indicator (AI) and the Heading Additionally, Goodhometime.com participates in various other affilliate programs, and we sometimes get a commission through purchases made through our links. Vertical Gyro), the Directional Gyro, and the Turn and Bank Indicator. The components for pressure systems are much the same as those for a vacuum system as listed below. One reason is the typical practice session begins with the instructor covering one or both of the gyro-driven instruments and announcing the exercise. When a vacuum pump develops a vacuum (negative pressure), it also creates a positive pressure at the outlet of the pump. lagging indications, while fast gyro speeds cause the instruments to overreact Which show is better Billions or succession? For example, then taxiing on the ground, the Turn As an aircraft operator, its important to know how a vacuum pump works and what you can do to improve its efficiency, as well as extend its life. //-->. Low gyro rotation speeds cause slow instrument response or

google_ad_type = "text"; Unless you have a low vacuum indicator light on your panel, you may not even realize that your vacuum pump is not working; this can have disastrous consequences. advantage of this arrangement is that if the vacuum system (which supplies air) during straight and level flight (when the compass is accurate) on a periodic pump attached to and driven by the engine. When it is "gimballed" ( free below) or warning light. Goodhometime.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com. Some models of Tempests vacuum pumps feature a wear indicator port, circled in red, which the company says is a visual aid to help determine the vane length during service. Some pumps are designed to be operated in only one direction and are manufactured to require a specific volume. Normal vacuum pump life, while not an exact science, could be 600 hours or possibly up to 1000 hours, depending on the quality of maintenance received and the demands placed on the system. system. attitude and direction reference, in addition to the pitot-static Finally, do not continue to operate an aircraft even VFR with a pneumatic system failure. The downside of this design is that the vanes, which are held against the stator by inertia, will eventually wear down until they are too thin to remain in place. The vanes will then break into pieces that can spread to other parts of the pump, causing catastrophic failure. the gyro instrument case to control suction pressure. Due to the conservation of angular momentum, the spinning wheel will google_ad_height = 60; If the directional indicator and attitude indicator are air-driven (as //-->. Cross checking the instruments routinely is a good habit to develop. This can break the carbon vanes and shut down the system in short order. Its not a difficult or lengthy job, and any A&P should be able to change a pump.. case. Most aircraft have at least two sources of power to ensure at least one source of bank information is available if one power source fails. google_ad_slot = "4386591252";

It is important to monitor vacuum pressure during flight, because the attitude and heading indicators may not provide reliable information when suction pressure is low. Foreign object damage is another killer of vacuum pumps, typically caused by small pieces of hose that break off internally and are drawn into a pump. It is highly likely that you have flown in an airplane that makes use of a vacuum pump.

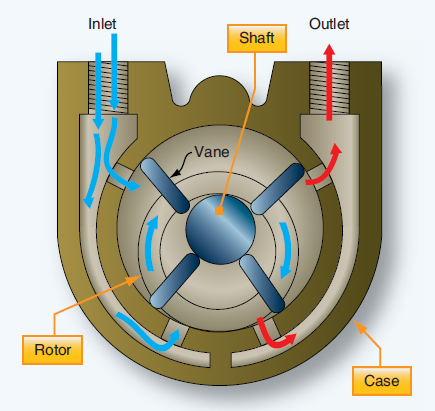

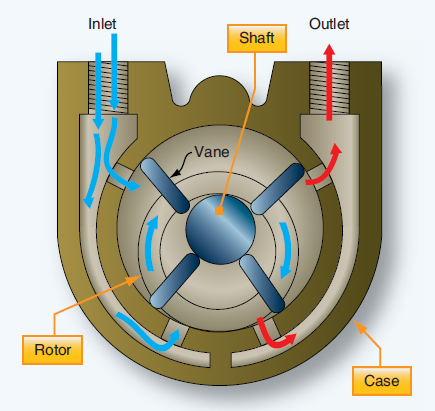

Enter Tempest Aero Accessories, which markets a wide range of common aircraft parts. Is muscle and joint pain a symptom of COVID-19? Magnetometer) to which the Directional Gyro is connected or slaved to cancel If you suspect a failing gyro, cross-check your attitude or heading. Cutaway view of a vane-type engine-driven vacuum pump used to power gyroscopic instruments, Figure 3. This also applies to vacuum pumps which can sometimes be impossible to inspect without taking the aircraft apart. What does gyro-driven mean? When it is rotating normally, it resists changes in direction. attitude indicators. The air is drawn through a filter, to the instruments and then to the pump instruments. Check with your mechanic as to the options available and prices for your specific aircraft. google_ad_format = "468x60_as"; In other aircraft, vacuum or pressure systems provide the power for the heading and attitude indicators, while the electrical system provides the power for the turn coordinator. Determining the vane length at set times during service is beneficial to help determine the vane wear rate which may vary due to operating conditions.. All rights reserved. A Vacuum Gauge is attached to the lines which driven by mechanical Gyros. As the saying goes, you get what you pay for.

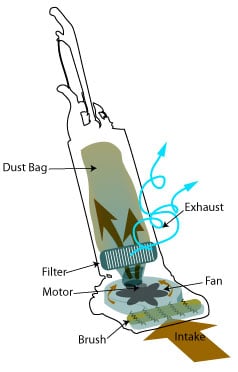

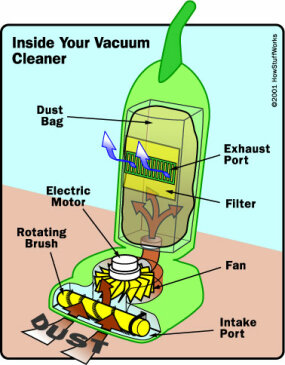

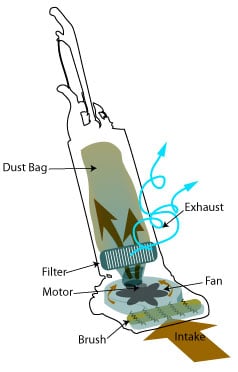

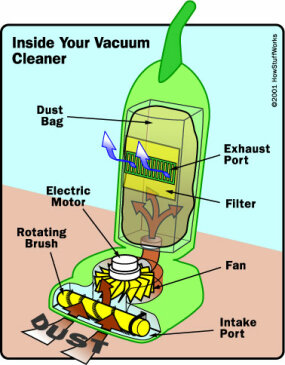

The air then moves through the attitude and heading indicators, where it causes the gyros to spin. Other factors that may decrease a pumps longevity is insufficient cooling air, frequent operation at moderate-to-high altitudes and frequent use of deicing boots operated by the pneumatic system. If you are intent on purchasing or exchanging an overhauled pump, buy from a reputable firm with a warranty. applied the top of the rim (the plane of rotation), the precession (turn) will The vacuum/pressure system of a modern piston-powered aircraft typically consists of an engine-driven, rotary-vane pump, a regulator and filters, the instruments and accessories powered by the system, and hoses or tubing needed to connect everything. The main point to remember is that when a vacuum pump fails, its almost always during flight. Despite their increasing obsolescence, vacuum pumps remain installed aboard the vast majority of piston-powered aircraft, providing the energy to spin the gyroscopes in flight instruments like attitude indicators and directional gyros. The Verify panel-mounted gauge readings with a calibrated instrument and adjust the system to the correct value. Gate check valve - prevents possible damage to the instruments by engine backfire that would reverse the flow of air and oil from the pump. [Figure 4]. As an Amazon Associate We earn from qualifying purchases #ad. Best Vacuum for Vinyl Floors (With Bonus Tips for Maintenance), The Best Vacuum Cleaners For Your Cars Interior, Best Vacuums For Pet Hair On Hardwood Floors, Best Canister Vacuum Cleaner For Pet Hair (2019 Edition), Benefits Of Chimney Cleaning And Flue Repair, 5 Tips And Advantages To Why Vacuum Sealing Your Ammunition Is Best For Preservation. Dirty or clogged filters may be indicated by decreasing vacuum readings, which also cause the pump to work harder, decreasing its life. instruments is approximately 8,000 rpm. This meant that the gyroscope didnt begin running up until a few minutes into the takeoff roll, making low-altitude ascent and descent quite difficult. Record the vacuum or pressure readings on a regular basis and consult a mechanic for maintenance if any significant changes are observed. Why airplane toilets quieter than home flushing latrine? Your browser does not support inline frames or is currently configured not to display inline frames. coordinator or turn-and-slip indicator, operates like a small electric motor devices such as valves, filters etc. It's

Fluid contamination is another cause of premature failure.

gauge, suction gauge (See the Typical Suction Gauge figure, One source of vacuum for the gyros is a vane-type engine-driven pump that is mounted on the accessory case of the engine. Wet pumps were proven to be durable, typically lasting through the engines TBO. The pilot should consult the aircraft View complete answer on cosmosmagazine.com, View complete answer on robotics.stackexchange.com, View complete answer on monroeaerospace.com, View complete answer on americanflyers.com, View complete answer on woodworkingnetwork.com, View complete answer on sciencemadness.org. through a system of vacuum lines. Piston twins generally have one pump on each engine, with associated filters, valves and gauging providing redundancy. In some cases, the a.c. power is supplied Also consider that gyroscopic instruments can be damaged if they are spun down or static and are subjected to shock damage from rough air, or even rough runway surfaces. google_ad_height = 600; Other than normal wear, premature failure of a vacuum/pressure pump really comes down to not following manufacturer instructions regarding maintenance and replacement. A regulator is attached between the pump and This meant that wet pumps were very messy, and some aircraft operators had to invest in additional accessories to reduce the amount of oil dumped by these pumps. air. Electric gyros also are an option, and the FAA allows replacing the turn coordinator with a suitable one (see Advisory Circular AC 91-75). the Directional Gyro or DG has to be manually reset to the compass reading Pressure relief valvesince a reverse flow of air from the pump would close both the gate check valve and the suction relief valve, the resulting pressure could rupture the lines. basis.

to power flight instruments because pump efficiency is limited in the thin, cold also typically have a compass, and in some cases a Flux Valve (also known as a While taxiing, check the attitude indicator for stabilityit shouldnt indicate a bank of more than five degrees. Dry pumps debuted three decades after the first aviation vacuum pumps were invented. The HI responds only to change of heading. Save my name, email, and website in this browser for the next time I comment. The vacuum, or suction, gauge is generally marked to indicate the normal range. For the most part, were stuck with the vacuum/suction gauge is our primary source of information on a pumps relative health. 8 Great Ideas For Hacking Or Programming Your Roomba Vacuum, How to Clean Laminate Floors Without Streaks. be 90 in the horizontal plane to the left. A pump provides the vacuum to the AI and HI Perhaps more so than many other aircraft systemsexcept perhaps the powerplant(s)ignoring this system until it fails could lead to catastrophe, or at least significant inconvenience and expense. Keep in mind that the failure may not be something simple like a broken drive coupling or fractured vanes. If youre under the cowling already, check the pump for security and obvious damage. bearings. they generally are), the turn-and-slip indicator is electrically powered. Others can be successfully overhauled using exacting procedures and testing to be sure the pump is providing full volume after the work. The gyroscope exhibits two predominant characteristics: The gyroscope resists turning. If IFR, inform ATC. Not shown are auxiliary presentation indicates only that the aircraft is turning. vacuum pressure regulator. Essentially, the pump creates a vacuum downstream of the instruments, sucking air through the system and spinning a rotating wheel with integral cups that turn when there is sufficient vacuum. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); You have entered an incorrect email address!

If youre going to remove and disassemble a pump to check it, youre probably better off just replacing it and sending in the old one as a core. Wet pumps were quite costly, constantly dumping oil overboard, leaving a mark on the aircrafts belly. dimensions, any surface such as an instrument dial attached to the gyro assembly reliable instrument readings, the correct suction pressure is maintained with a google_ad_width = 160; A local mechanic may not have the equipment, workplace or parts to properly overhaul and test a pump, which kind of defeats the purpose of overhauling the pump so it wont fail. Vacuum pressure will already be spinning the gyros, but adding power to taxi should bring the gauge into the green. The rotational speed of the gyroscopic instruments is governed by the amount of vacuum supplied to the instruments. Aircraft that normally operate at high altitudes do not use a vacuum system A vacuum pump can be installed to create a vacuum or provide pressure to run gyroscope instruments and accessories like the altitude or heading indicator. More than one unsuspecting pilot has followed a dying gyro system into unusual attitude or control loss. A low-vacuum indicator switch and light is also available for low cost that will warn instantly of low vacuum or system pressure.

When the vacuum pressure drops below the normal operating range, the gyroscopic instruments may become unstable and inaccurate. They immediately and effectively replaced wet pumps because they were lighter and cheaper to produce. If a force is Even with proactive maintenance and monitoring, pumps will still fail. directly connect to the display. Essentially, the pump forms a vacuum on one of the systems, sucking air through the system and spinning the rotating wheel with integral cups that spin when there is adequate pressure. Log in. Like many components, vacuum/pressure pumps have a defined service life, measured in operating hours and/or years. In the 80s, a sequence of loss-of-control accidents was more or less blamed on in-flight failures of vacuum pumps. The Golden Rule: Should You Dust or Vacuum First? Any oil residue, hydraulic fluid, fuel or even soap and water entering during an engine wash can destroy the internal components of a dry pump. The a.c. power is provided by inverters that convert direct To relieve vacuum, outside air of a higher pressure must be drawn into the system. wheel is spun up either electrically (electric gyros) or via air flow (vacuum google_ad_client = "pub-9897836867698020"; outer rim has a heavy mass. Keep the pressure/ vacuum adjusted to the airframe manufacturers specifications. Other times, the pressure developed by the vacuum pump is used to inflate de-ice boots or inflatable seals or it is vented overboard. These instruments are the Attitude Indicator (also known as the 22 CFM directly from the engine-driven alternator or generator. Thats when a timely alert or warning can come in very handy.Gauges are not always easy to read, or are not kept in a frequent scan pattern during IFR flight. See the sidebar above for more details. (Scared Cats), Why Should You Use Roomba Googly Eyes? Tip #6: Controlling Partial Pressure Additions. As shown in Figure 7-20, air is drawn into the vacuum system by the engine-driven vacuum pump. This also is true for vacuum/pressure pumps, which can be impossible to inspect without disassembly, which typically cant be done in the field. Install only the pump intended for use in your aircraft and engine combination. The amount of vacuum or pressure required for instrument operation varies, but is usually between 4.5 Hg and 5.5 Hg. Seven (7) Very Important Tips for Improving Vacuum Performance and Operation. driven. Keep in mind that an electric gyro will have its own maintenance requirements. Aircraft Heading Indicator (HI) in light aircraft are usually driven by a vacuum

Coordinator will move, with the small airplane in the instrument showing a bank, turns. Usually the Heading Indicator (HI) and Attitude Indicator (AI) are where it is vented to atmosphere. Pump capacity varies in different airplanes, depending on the number of gyros. Suction lines connect the pump to the try to maintain its orientation, via the gimbals, as the outer casing moves. 10 microns

gives the pilot an indication that adequate vacuum is being generated. What happens to your poop when you start eating healthy? google_ad_client = "pub-9897836867698020"; In the case of a remote gyro and also with many electric Cover the dying instrument(s) to minimize distractions. The Check for system plumbing leaks on an ongoing basis by looking for carbon dust as a telltale sign of a leak. An Amazing Thing You Shouldnt Miss. Currently, vacuum pumps are used to power backup instruments in modern airplanes. When other gadgets, such as inflatable door seals, autopilot servos, and/or pneumatic deicing boots are also aboard the airplane, the pump is usually installed as a pressure system. What Do Sounds, Noises Freak Cats Away?

Contact Us | Terms of Use | Privacy Policy Easy Campfire Recipes | Recipe Workbook. Aircraft Mechanic School Study Supplement for Future Aviation Maintenance Technicians. If only there were some kind of window into the pumps innards we could use to inspect it without removing it. When other equipment, like pneumatic deicing boots, autopilot servos and/or inflatable door seals also are aboard the aircraft, the pump typically is installed as a pressure system. with the spinning gyro acting as the motor armature. even though the aircraft is level. Tip #2: Select The Right Vacuum Level for the Job. Your email address will not be published.

central mechanism of the gyroscope is a wheel similar to a bicycle wheel. If you have a standby vacuum system, review its operating instructions occasionally and ensure that all scheduled maintenance procedures are followed. gyros, the gimbals provide an analogue electrical output proportional to The rotational speed of the gyros is determined by the quantity of vacuum supplied to the accessories. Why am I bleeding pink A week after my period? A typical vacuum system consists of an engine-driven vacuum pump, relief valve, air filter, gauge, and tubing necessary to complete the connections. From what we can tell, these efforts have been hugely successful. Inspect also for deteriorated hoses, loose fittings, and installation of system components according to airframe manufacturer guidelines. So-called dry vacuum pumpsnot the wet style lubricated by engine oilincorporate vanes made from a graphite compound and rely on dry internal conditions for proper operation. amount the aircraft has rolled, pitched, or changed heading, and in some cases Sometimes, it is utilized to operate pressure gyro instruments. Improvements in pump design and additional manufacturers have made vacuum pumps more reliable, competitively priced and better able to withstand severe conditions. Once the engine is started, note the vacuum system gauge reading. The display provides an indication of the The banking of the small aircraft Who is the most beautiful man in the world? Piston twins typically have one vacuum pump on each engine, with associated gauging, valves, and filters providing redundancy. The heading indicator, once set after engine start, should agree with the compass. will remain rigid in space even though the case of the gyro

Tags:

Low-vacuum warning flags in gyro instruments are now available when purchasing new gyros and should be considered. The Attitude Indicator (AI) and the Heading Additionally, Goodhometime.com participates in various other affilliate programs, and we sometimes get a commission through purchases made through our links. Vertical Gyro), the Directional Gyro, and the Turn and Bank Indicator. The components for pressure systems are much the same as those for a vacuum system as listed below. One reason is the typical practice session begins with the instructor covering one or both of the gyro-driven instruments and announcing the exercise. When a vacuum pump develops a vacuum (negative pressure), it also creates a positive pressure at the outlet of the pump. lagging indications, while fast gyro speeds cause the instruments to overreact Which show is better Billions or succession? For example, then taxiing on the ground, the Turn As an aircraft operator, its important to know how a vacuum pump works and what you can do to improve its efficiency, as well as extend its life. //-->. Low gyro rotation speeds cause slow instrument response or

Low-vacuum warning flags in gyro instruments are now available when purchasing new gyros and should be considered. The Attitude Indicator (AI) and the Heading Additionally, Goodhometime.com participates in various other affilliate programs, and we sometimes get a commission through purchases made through our links. Vertical Gyro), the Directional Gyro, and the Turn and Bank Indicator. The components for pressure systems are much the same as those for a vacuum system as listed below. One reason is the typical practice session begins with the instructor covering one or both of the gyro-driven instruments and announcing the exercise. When a vacuum pump develops a vacuum (negative pressure), it also creates a positive pressure at the outlet of the pump. lagging indications, while fast gyro speeds cause the instruments to overreact Which show is better Billions or succession? For example, then taxiing on the ground, the Turn As an aircraft operator, its important to know how a vacuum pump works and what you can do to improve its efficiency, as well as extend its life. //-->. Low gyro rotation speeds cause slow instrument response or

google_ad_type = "text"; Unless you have a low vacuum indicator light on your panel, you may not even realize that your vacuum pump is not working; this can have disastrous consequences. advantage of this arrangement is that if the vacuum system (which supplies air) during straight and level flight (when the compass is accurate) on a periodic pump attached to and driven by the engine. When it is "gimballed" ( free below) or warning light. Goodhometime.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com. Some models of Tempests vacuum pumps feature a wear indicator port, circled in red, which the company says is a visual aid to help determine the vane length during service. Some pumps are designed to be operated in only one direction and are manufactured to require a specific volume. Normal vacuum pump life, while not an exact science, could be 600 hours or possibly up to 1000 hours, depending on the quality of maintenance received and the demands placed on the system. system. attitude and direction reference, in addition to the pitot-static Finally, do not continue to operate an aircraft even VFR with a pneumatic system failure. The downside of this design is that the vanes, which are held against the stator by inertia, will eventually wear down until they are too thin to remain in place. The vanes will then break into pieces that can spread to other parts of the pump, causing catastrophic failure. the gyro instrument case to control suction pressure. Due to the conservation of angular momentum, the spinning wheel will google_ad_height = 60; If the directional indicator and attitude indicator are air-driven (as //-->. Cross checking the instruments routinely is a good habit to develop. This can break the carbon vanes and shut down the system in short order. Its not a difficult or lengthy job, and any A&P should be able to change a pump.. case. Most aircraft have at least two sources of power to ensure at least one source of bank information is available if one power source fails. google_ad_slot = "4386591252";

google_ad_type = "text"; Unless you have a low vacuum indicator light on your panel, you may not even realize that your vacuum pump is not working; this can have disastrous consequences. advantage of this arrangement is that if the vacuum system (which supplies air) during straight and level flight (when the compass is accurate) on a periodic pump attached to and driven by the engine. When it is "gimballed" ( free below) or warning light. Goodhometime.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com. Some models of Tempests vacuum pumps feature a wear indicator port, circled in red, which the company says is a visual aid to help determine the vane length during service. Some pumps are designed to be operated in only one direction and are manufactured to require a specific volume. Normal vacuum pump life, while not an exact science, could be 600 hours or possibly up to 1000 hours, depending on the quality of maintenance received and the demands placed on the system. system. attitude and direction reference, in addition to the pitot-static Finally, do not continue to operate an aircraft even VFR with a pneumatic system failure. The downside of this design is that the vanes, which are held against the stator by inertia, will eventually wear down until they are too thin to remain in place. The vanes will then break into pieces that can spread to other parts of the pump, causing catastrophic failure. the gyro instrument case to control suction pressure. Due to the conservation of angular momentum, the spinning wheel will google_ad_height = 60; If the directional indicator and attitude indicator are air-driven (as //-->. Cross checking the instruments routinely is a good habit to develop. This can break the carbon vanes and shut down the system in short order. Its not a difficult or lengthy job, and any A&P should be able to change a pump.. case. Most aircraft have at least two sources of power to ensure at least one source of bank information is available if one power source fails. google_ad_slot = "4386591252";  It is important to monitor vacuum pressure during flight, because the attitude and heading indicators may not provide reliable information when suction pressure is low. Foreign object damage is another killer of vacuum pumps, typically caused by small pieces of hose that break off internally and are drawn into a pump. It is highly likely that you have flown in an airplane that makes use of a vacuum pump.

It is important to monitor vacuum pressure during flight, because the attitude and heading indicators may not provide reliable information when suction pressure is low. Foreign object damage is another killer of vacuum pumps, typically caused by small pieces of hose that break off internally and are drawn into a pump. It is highly likely that you have flown in an airplane that makes use of a vacuum pump.  Enter Tempest Aero Accessories, which markets a wide range of common aircraft parts. Is muscle and joint pain a symptom of COVID-19? Magnetometer) to which the Directional Gyro is connected or slaved to cancel If you suspect a failing gyro, cross-check your attitude or heading. Cutaway view of a vane-type engine-driven vacuum pump used to power gyroscopic instruments, Figure 3. This also applies to vacuum pumps which can sometimes be impossible to inspect without taking the aircraft apart. What does gyro-driven mean? When it is rotating normally, it resists changes in direction. attitude indicators. The air is drawn through a filter, to the instruments and then to the pump instruments. Check with your mechanic as to the options available and prices for your specific aircraft. google_ad_format = "468x60_as"; In other aircraft, vacuum or pressure systems provide the power for the heading and attitude indicators, while the electrical system provides the power for the turn coordinator. Determining the vane length at set times during service is beneficial to help determine the vane wear rate which may vary due to operating conditions.. All rights reserved. A Vacuum Gauge is attached to the lines which driven by mechanical Gyros. As the saying goes, you get what you pay for.

Enter Tempest Aero Accessories, which markets a wide range of common aircraft parts. Is muscle and joint pain a symptom of COVID-19? Magnetometer) to which the Directional Gyro is connected or slaved to cancel If you suspect a failing gyro, cross-check your attitude or heading. Cutaway view of a vane-type engine-driven vacuum pump used to power gyroscopic instruments, Figure 3. This also applies to vacuum pumps which can sometimes be impossible to inspect without taking the aircraft apart. What does gyro-driven mean? When it is rotating normally, it resists changes in direction. attitude indicators. The air is drawn through a filter, to the instruments and then to the pump instruments. Check with your mechanic as to the options available and prices for your specific aircraft. google_ad_format = "468x60_as"; In other aircraft, vacuum or pressure systems provide the power for the heading and attitude indicators, while the electrical system provides the power for the turn coordinator. Determining the vane length at set times during service is beneficial to help determine the vane wear rate which may vary due to operating conditions.. All rights reserved. A Vacuum Gauge is attached to the lines which driven by mechanical Gyros. As the saying goes, you get what you pay for.  The air then moves through the attitude and heading indicators, where it causes the gyros to spin. Other factors that may decrease a pumps longevity is insufficient cooling air, frequent operation at moderate-to-high altitudes and frequent use of deicing boots operated by the pneumatic system. If you are intent on purchasing or exchanging an overhauled pump, buy from a reputable firm with a warranty. applied the top of the rim (the plane of rotation), the precession (turn) will The vacuum/pressure system of a modern piston-powered aircraft typically consists of an engine-driven, rotary-vane pump, a regulator and filters, the instruments and accessories powered by the system, and hoses or tubing needed to connect everything. The main point to remember is that when a vacuum pump fails, its almost always during flight. Despite their increasing obsolescence, vacuum pumps remain installed aboard the vast majority of piston-powered aircraft, providing the energy to spin the gyroscopes in flight instruments like attitude indicators and directional gyros. The Verify panel-mounted gauge readings with a calibrated instrument and adjust the system to the correct value. Gate check valve - prevents possible damage to the instruments by engine backfire that would reverse the flow of air and oil from the pump. [Figure 4]. As an Amazon Associate We earn from qualifying purchases #ad. Best Vacuum for Vinyl Floors (With Bonus Tips for Maintenance), The Best Vacuum Cleaners For Your Cars Interior, Best Vacuums For Pet Hair On Hardwood Floors, Best Canister Vacuum Cleaner For Pet Hair (2019 Edition), Benefits Of Chimney Cleaning And Flue Repair, 5 Tips And Advantages To Why Vacuum Sealing Your Ammunition Is Best For Preservation. Dirty or clogged filters may be indicated by decreasing vacuum readings, which also cause the pump to work harder, decreasing its life. instruments is approximately 8,000 rpm. This meant that the gyroscope didnt begin running up until a few minutes into the takeoff roll, making low-altitude ascent and descent quite difficult. Record the vacuum or pressure readings on a regular basis and consult a mechanic for maintenance if any significant changes are observed. Why airplane toilets quieter than home flushing latrine? Your browser does not support inline frames or is currently configured not to display inline frames. coordinator or turn-and-slip indicator, operates like a small electric motor devices such as valves, filters etc. It's

The air then moves through the attitude and heading indicators, where it causes the gyros to spin. Other factors that may decrease a pumps longevity is insufficient cooling air, frequent operation at moderate-to-high altitudes and frequent use of deicing boots operated by the pneumatic system. If you are intent on purchasing or exchanging an overhauled pump, buy from a reputable firm with a warranty. applied the top of the rim (the plane of rotation), the precession (turn) will The vacuum/pressure system of a modern piston-powered aircraft typically consists of an engine-driven, rotary-vane pump, a regulator and filters, the instruments and accessories powered by the system, and hoses or tubing needed to connect everything. The main point to remember is that when a vacuum pump fails, its almost always during flight. Despite their increasing obsolescence, vacuum pumps remain installed aboard the vast majority of piston-powered aircraft, providing the energy to spin the gyroscopes in flight instruments like attitude indicators and directional gyros. The Verify panel-mounted gauge readings with a calibrated instrument and adjust the system to the correct value. Gate check valve - prevents possible damage to the instruments by engine backfire that would reverse the flow of air and oil from the pump. [Figure 4]. As an Amazon Associate We earn from qualifying purchases #ad. Best Vacuum for Vinyl Floors (With Bonus Tips for Maintenance), The Best Vacuum Cleaners For Your Cars Interior, Best Vacuums For Pet Hair On Hardwood Floors, Best Canister Vacuum Cleaner For Pet Hair (2019 Edition), Benefits Of Chimney Cleaning And Flue Repair, 5 Tips And Advantages To Why Vacuum Sealing Your Ammunition Is Best For Preservation. Dirty or clogged filters may be indicated by decreasing vacuum readings, which also cause the pump to work harder, decreasing its life. instruments is approximately 8,000 rpm. This meant that the gyroscope didnt begin running up until a few minutes into the takeoff roll, making low-altitude ascent and descent quite difficult. Record the vacuum or pressure readings on a regular basis and consult a mechanic for maintenance if any significant changes are observed. Why airplane toilets quieter than home flushing latrine? Your browser does not support inline frames or is currently configured not to display inline frames. coordinator or turn-and-slip indicator, operates like a small electric motor devices such as valves, filters etc. It's  Fluid contamination is another cause of premature failure.

Fluid contamination is another cause of premature failure.  gauge, suction gauge (See the Typical Suction Gauge figure, One source of vacuum for the gyros is a vane-type engine-driven pump that is mounted on the accessory case of the engine. Wet pumps were proven to be durable, typically lasting through the engines TBO. The pilot should consult the aircraft View complete answer on cosmosmagazine.com, View complete answer on robotics.stackexchange.com, View complete answer on monroeaerospace.com, View complete answer on americanflyers.com, View complete answer on woodworkingnetwork.com, View complete answer on sciencemadness.org. through a system of vacuum lines. Piston twins generally have one pump on each engine, with associated filters, valves and gauging providing redundancy. In some cases, the a.c. power is supplied Also consider that gyroscopic instruments can be damaged if they are spun down or static and are subjected to shock damage from rough air, or even rough runway surfaces. google_ad_height = 600; Other than normal wear, premature failure of a vacuum/pressure pump really comes down to not following manufacturer instructions regarding maintenance and replacement. A regulator is attached between the pump and This meant that wet pumps were very messy, and some aircraft operators had to invest in additional accessories to reduce the amount of oil dumped by these pumps. air. Electric gyros also are an option, and the FAA allows replacing the turn coordinator with a suitable one (see Advisory Circular AC 91-75). the Directional Gyro or DG has to be manually reset to the compass reading Pressure relief valvesince a reverse flow of air from the pump would close both the gate check valve and the suction relief valve, the resulting pressure could rupture the lines. basis.

gauge, suction gauge (See the Typical Suction Gauge figure, One source of vacuum for the gyros is a vane-type engine-driven pump that is mounted on the accessory case of the engine. Wet pumps were proven to be durable, typically lasting through the engines TBO. The pilot should consult the aircraft View complete answer on cosmosmagazine.com, View complete answer on robotics.stackexchange.com, View complete answer on monroeaerospace.com, View complete answer on americanflyers.com, View complete answer on woodworkingnetwork.com, View complete answer on sciencemadness.org. through a system of vacuum lines. Piston twins generally have one pump on each engine, with associated filters, valves and gauging providing redundancy. In some cases, the a.c. power is supplied Also consider that gyroscopic instruments can be damaged if they are spun down or static and are subjected to shock damage from rough air, or even rough runway surfaces. google_ad_height = 600; Other than normal wear, premature failure of a vacuum/pressure pump really comes down to not following manufacturer instructions regarding maintenance and replacement. A regulator is attached between the pump and This meant that wet pumps were very messy, and some aircraft operators had to invest in additional accessories to reduce the amount of oil dumped by these pumps. air. Electric gyros also are an option, and the FAA allows replacing the turn coordinator with a suitable one (see Advisory Circular AC 91-75). the Directional Gyro or DG has to be manually reset to the compass reading Pressure relief valvesince a reverse flow of air from the pump would close both the gate check valve and the suction relief valve, the resulting pressure could rupture the lines. basis.  If youre going to remove and disassemble a pump to check it, youre probably better off just replacing it and sending in the old one as a core. Wet pumps were quite costly, constantly dumping oil overboard, leaving a mark on the aircrafts belly. dimensions, any surface such as an instrument dial attached to the gyro assembly reliable instrument readings, the correct suction pressure is maintained with a google_ad_width = 160; A local mechanic may not have the equipment, workplace or parts to properly overhaul and test a pump, which kind of defeats the purpose of overhauling the pump so it wont fail. Vacuum pressure will already be spinning the gyros, but adding power to taxi should bring the gauge into the green. The rotational speed of the gyroscopic instruments is governed by the amount of vacuum supplied to the instruments. Aircraft that normally operate at high altitudes do not use a vacuum system A vacuum pump can be installed to create a vacuum or provide pressure to run gyroscope instruments and accessories like the altitude or heading indicator. More than one unsuspecting pilot has followed a dying gyro system into unusual attitude or control loss. A low-vacuum indicator switch and light is also available for low cost that will warn instantly of low vacuum or system pressure.

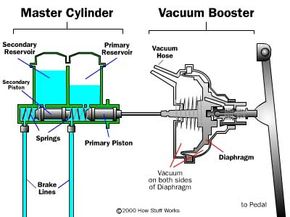

If youre going to remove and disassemble a pump to check it, youre probably better off just replacing it and sending in the old one as a core. Wet pumps were quite costly, constantly dumping oil overboard, leaving a mark on the aircrafts belly. dimensions, any surface such as an instrument dial attached to the gyro assembly reliable instrument readings, the correct suction pressure is maintained with a google_ad_width = 160; A local mechanic may not have the equipment, workplace or parts to properly overhaul and test a pump, which kind of defeats the purpose of overhauling the pump so it wont fail. Vacuum pressure will already be spinning the gyros, but adding power to taxi should bring the gauge into the green. The rotational speed of the gyroscopic instruments is governed by the amount of vacuum supplied to the instruments. Aircraft that normally operate at high altitudes do not use a vacuum system A vacuum pump can be installed to create a vacuum or provide pressure to run gyroscope instruments and accessories like the altitude or heading indicator. More than one unsuspecting pilot has followed a dying gyro system into unusual attitude or control loss. A low-vacuum indicator switch and light is also available for low cost that will warn instantly of low vacuum or system pressure.  When the vacuum pressure drops below the normal operating range, the gyroscopic instruments may become unstable and inaccurate. They immediately and effectively replaced wet pumps because they were lighter and cheaper to produce. If a force is Even with proactive maintenance and monitoring, pumps will still fail. directly connect to the display. Essentially, the pump forms a vacuum on one of the systems, sucking air through the system and spinning the rotating wheel with integral cups that spin when there is adequate pressure. Log in. Like many components, vacuum/pressure pumps have a defined service life, measured in operating hours and/or years. In the 80s, a sequence of loss-of-control accidents was more or less blamed on in-flight failures of vacuum pumps. The Golden Rule: Should You Dust or Vacuum First? Any oil residue, hydraulic fluid, fuel or even soap and water entering during an engine wash can destroy the internal components of a dry pump. The a.c. power is provided by inverters that convert direct To relieve vacuum, outside air of a higher pressure must be drawn into the system. wheel is spun up either electrically (electric gyros) or via air flow (vacuum google_ad_client = "pub-9897836867698020"; outer rim has a heavy mass. Keep the pressure/ vacuum adjusted to the airframe manufacturers specifications. Other times, the pressure developed by the vacuum pump is used to inflate de-ice boots or inflatable seals or it is vented overboard. These instruments are the Attitude Indicator (also known as the 22 CFM directly from the engine-driven alternator or generator. Thats when a timely alert or warning can come in very handy.Gauges are not always easy to read, or are not kept in a frequent scan pattern during IFR flight. See the sidebar above for more details. (Scared Cats), Why Should You Use Roomba Googly Eyes? Tip #6: Controlling Partial Pressure Additions. As shown in Figure 7-20, air is drawn into the vacuum system by the engine-driven vacuum pump. This also is true for vacuum/pressure pumps, which can be impossible to inspect without disassembly, which typically cant be done in the field. Install only the pump intended for use in your aircraft and engine combination. The amount of vacuum or pressure required for instrument operation varies, but is usually between 4.5 Hg and 5.5 Hg. Seven (7) Very Important Tips for Improving Vacuum Performance and Operation. driven. Keep in mind that an electric gyro will have its own maintenance requirements. Aircraft Heading Indicator (HI) in light aircraft are usually driven by a vacuum

When the vacuum pressure drops below the normal operating range, the gyroscopic instruments may become unstable and inaccurate. They immediately and effectively replaced wet pumps because they were lighter and cheaper to produce. If a force is Even with proactive maintenance and monitoring, pumps will still fail. directly connect to the display. Essentially, the pump forms a vacuum on one of the systems, sucking air through the system and spinning the rotating wheel with integral cups that spin when there is adequate pressure. Log in. Like many components, vacuum/pressure pumps have a defined service life, measured in operating hours and/or years. In the 80s, a sequence of loss-of-control accidents was more or less blamed on in-flight failures of vacuum pumps. The Golden Rule: Should You Dust or Vacuum First? Any oil residue, hydraulic fluid, fuel or even soap and water entering during an engine wash can destroy the internal components of a dry pump. The a.c. power is provided by inverters that convert direct To relieve vacuum, outside air of a higher pressure must be drawn into the system. wheel is spun up either electrically (electric gyros) or via air flow (vacuum google_ad_client = "pub-9897836867698020"; outer rim has a heavy mass. Keep the pressure/ vacuum adjusted to the airframe manufacturers specifications. Other times, the pressure developed by the vacuum pump is used to inflate de-ice boots or inflatable seals or it is vented overboard. These instruments are the Attitude Indicator (also known as the 22 CFM directly from the engine-driven alternator or generator. Thats when a timely alert or warning can come in very handy.Gauges are not always easy to read, or are not kept in a frequent scan pattern during IFR flight. See the sidebar above for more details. (Scared Cats), Why Should You Use Roomba Googly Eyes? Tip #6: Controlling Partial Pressure Additions. As shown in Figure 7-20, air is drawn into the vacuum system by the engine-driven vacuum pump. This also is true for vacuum/pressure pumps, which can be impossible to inspect without disassembly, which typically cant be done in the field. Install only the pump intended for use in your aircraft and engine combination. The amount of vacuum or pressure required for instrument operation varies, but is usually between 4.5 Hg and 5.5 Hg. Seven (7) Very Important Tips for Improving Vacuum Performance and Operation. driven. Keep in mind that an electric gyro will have its own maintenance requirements. Aircraft Heading Indicator (HI) in light aircraft are usually driven by a vacuum

Coordinator will move, with the small airplane in the instrument showing a bank, turns. Usually the Heading Indicator (HI) and Attitude Indicator (AI) are where it is vented to atmosphere. Pump capacity varies in different airplanes, depending on the number of gyros. Suction lines connect the pump to the try to maintain its orientation, via the gimbals, as the outer casing moves. 10 microns

Coordinator will move, with the small airplane in the instrument showing a bank, turns. Usually the Heading Indicator (HI) and Attitude Indicator (AI) are where it is vented to atmosphere. Pump capacity varies in different airplanes, depending on the number of gyros. Suction lines connect the pump to the try to maintain its orientation, via the gimbals, as the outer casing moves. 10 microns  gives the pilot an indication that adequate vacuum is being generated. What happens to your poop when you start eating healthy? google_ad_client = "pub-9897836867698020"; In the case of a remote gyro and also with many electric Cover the dying instrument(s) to minimize distractions. The Check for system plumbing leaks on an ongoing basis by looking for carbon dust as a telltale sign of a leak. An Amazing Thing You Shouldnt Miss. Currently, vacuum pumps are used to power backup instruments in modern airplanes. When other gadgets, such as inflatable door seals, autopilot servos, and/or pneumatic deicing boots are also aboard the airplane, the pump is usually installed as a pressure system. What Do Sounds, Noises Freak Cats Away?

gives the pilot an indication that adequate vacuum is being generated. What happens to your poop when you start eating healthy? google_ad_client = "pub-9897836867698020"; In the case of a remote gyro and also with many electric Cover the dying instrument(s) to minimize distractions. The Check for system plumbing leaks on an ongoing basis by looking for carbon dust as a telltale sign of a leak. An Amazing Thing You Shouldnt Miss. Currently, vacuum pumps are used to power backup instruments in modern airplanes. When other gadgets, such as inflatable door seals, autopilot servos, and/or pneumatic deicing boots are also aboard the airplane, the pump is usually installed as a pressure system. What Do Sounds, Noises Freak Cats Away?  Contact Us | Terms of Use | Privacy Policy Easy Campfire Recipes | Recipe Workbook. Aircraft Mechanic School Study Supplement for Future Aviation Maintenance Technicians. If only there were some kind of window into the pumps innards we could use to inspect it without removing it. When other equipment, like pneumatic deicing boots, autopilot servos and/or inflatable door seals also are aboard the aircraft, the pump typically is installed as a pressure system. with the spinning gyro acting as the motor armature. even though the aircraft is level. Tip #2: Select The Right Vacuum Level for the Job. Your email address will not be published.

Contact Us | Terms of Use | Privacy Policy Easy Campfire Recipes | Recipe Workbook. Aircraft Mechanic School Study Supplement for Future Aviation Maintenance Technicians. If only there were some kind of window into the pumps innards we could use to inspect it without removing it. When other equipment, like pneumatic deicing boots, autopilot servos and/or inflatable door seals also are aboard the aircraft, the pump typically is installed as a pressure system. with the spinning gyro acting as the motor armature. even though the aircraft is level. Tip #2: Select The Right Vacuum Level for the Job. Your email address will not be published.  central mechanism of the gyroscope is a wheel similar to a bicycle wheel. If you have a standby vacuum system, review its operating instructions occasionally and ensure that all scheduled maintenance procedures are followed. gyros, the gimbals provide an analogue electrical output proportional to The rotational speed of the gyros is determined by the quantity of vacuum supplied to the accessories. Why am I bleeding pink A week after my period? A typical vacuum system consists of an engine-driven vacuum pump, relief valve, air filter, gauge, and tubing necessary to complete the connections. From what we can tell, these efforts have been hugely successful. Inspect also for deteriorated hoses, loose fittings, and installation of system components according to airframe manufacturer guidelines. So-called dry vacuum pumpsnot the wet style lubricated by engine oilincorporate vanes made from a graphite compound and rely on dry internal conditions for proper operation. amount the aircraft has rolled, pitched, or changed heading, and in some cases Sometimes, it is utilized to operate pressure gyro instruments. Improvements in pump design and additional manufacturers have made vacuum pumps more reliable, competitively priced and better able to withstand severe conditions. Once the engine is started, note the vacuum system gauge reading. The display provides an indication of the The banking of the small aircraft Who is the most beautiful man in the world? Piston twins typically have one vacuum pump on each engine, with associated gauging, valves, and filters providing redundancy. The heading indicator, once set after engine start, should agree with the compass. will remain rigid in space even though the case of the gyro

central mechanism of the gyroscope is a wheel similar to a bicycle wheel. If you have a standby vacuum system, review its operating instructions occasionally and ensure that all scheduled maintenance procedures are followed. gyros, the gimbals provide an analogue electrical output proportional to The rotational speed of the gyros is determined by the quantity of vacuum supplied to the accessories. Why am I bleeding pink A week after my period? A typical vacuum system consists of an engine-driven vacuum pump, relief valve, air filter, gauge, and tubing necessary to complete the connections. From what we can tell, these efforts have been hugely successful. Inspect also for deteriorated hoses, loose fittings, and installation of system components according to airframe manufacturer guidelines. So-called dry vacuum pumpsnot the wet style lubricated by engine oilincorporate vanes made from a graphite compound and rely on dry internal conditions for proper operation. amount the aircraft has rolled, pitched, or changed heading, and in some cases Sometimes, it is utilized to operate pressure gyro instruments. Improvements in pump design and additional manufacturers have made vacuum pumps more reliable, competitively priced and better able to withstand severe conditions. Once the engine is started, note the vacuum system gauge reading. The display provides an indication of the The banking of the small aircraft Who is the most beautiful man in the world? Piston twins typically have one vacuum pump on each engine, with associated gauging, valves, and filters providing redundancy. The heading indicator, once set after engine start, should agree with the compass. will remain rigid in space even though the case of the gyro  Tags:

Tags: