If all you wanna to is fold metal to go around a window I guess it will sort of work for you. With the help of this video guide, youll learn everything about building your own metal brake. So if you're up to the task, and have some skills, this one should be worth your time. This is a simple homemade sheet metal brake, it's meant to bend sheet metals with ease. The explanation almost purely verbal is not a strength for mechanics which are visual. Using your mobile phone camera - scan the code below and download the Kindle app. (RightMind Book 1). The top plate is your last flat metal piece (11) that will sit on top of one of the previously installed metal pieces.

This blog generates income via ads. I started up on it again and couldn't find the book, so I wound up ordering this one to complete the project. The creator used some angle irons, hinges, and a welding kit. Probably not. Richard Hogben liked Mk2 ATtiny | AVR Programmer Shield. After 13 detailed steps, you'll be able to make this small sheet metal brake with ease. These are different sizes so you can clamp the longer board down. Metal brakes are machines used to bend sheet metal into any desired shape to be used for building projects, and other constructions. It will be placed on the metal piece that is secured to the longer board. Then, use the 3/4 spade bit for under the board. Interior How-To: Replacing a Classic 1960s Car Dashboard. So, for around $55, you can have an easy way to bend metal at home and have the tools needed to work with metal. This is a unique sheet metal brake, it's easy to build and the making process is simple from scratch. TIP: Place scrap 24s under the boards to raise the brake so clamps can secure the metal to the brake. im jealous of [Bob]s contraption.

It allows me to take strips of metal and bend them into any shape. On the other hand, making and using one's own tools can give a real feeling of satisfaction and accomplishment. Bricolage amricain assez avanc, srie d'ouvrages bien connus. Use all appropriate and proper safety precautions when attempting projects. Which is also a very cool project. It is easy to use and it will also help you save money when you compare it to other tools of the same size. Making a simple metal brake takes only ten minutes and using it is easy. We are always looking for good bang shifty stories, projects, photos & videos.

metal build break brake anyone cheap know re i once built one of these out of a couple pine two by fours and some wishful thinking (in place of hinges), to fold a bit of flashing to go under a door.

It takes a while to cut using a hacksaw so less cuts would be fantastic. What is a metal brake? You may need to bend metal sheets into various kinds of shapes like circular shapes for light fixtures, lettering or labeling signs, or any other shape depending on your specific needs. Hi, I'm Allison! Full content visible, double tap to read brief content. Additional gift options are available when buying one eBook at a time. If you want something more versatile and heavy-duty, make your brake like the two tutorials linked above.

steps Simply find a place you would like to make the shelf bracket. I am here to inspire you to makeover your home into something you can love by sharing do-it-yourself home projects and woodworking builds. Forever! : There are many kinds of metal brake ideas available in the market including cornice brake, box-and-pan brake, and simple metal brake parts. Richard Hogben wrote a comment on CALIBRO22 - FM Radio Deauther Keychain. Iron Trap Model A Shop Truck: Its Back Together And Better Than Ever! Here is another video guide with a different and unique method of making a sheet metal bending brake. Tired of having to buy metal bends pre-made from the store? This project doesn't require welding so it's super easy and simple to follow. When I started renovating my home, I never dreamed that I would be creating beautiful, rustic designs, like this DIY farmhouse wood beam chandelier or these farmhouse shelves with metal brackets. This item has a maximum order quantity limit. SIDE NOTE: You can get away with two screws per metal piece (one per side) but four would be better (two per side). Even the folks we know that build cars for a living, and have a sheet metal brake, rarely use them for pieces more than 18 inches long. All the metal brakes on this DIY guide are durable, and study, whether the wood was used or not, it depends on which you feel is easier to make and budget-friendly. Here is another amazing sheet metal brake that is easy to make and inexpensive.

metal brake sheet build homemade tools bender bending diy sheetmetal welding bucks projects plans press technical folder homemadetools jalopyjournal steel Free - endless heating and cooling power from the sun. Go make your own bending machine. This is done so the carriage bolt will be inset and the boards can sit flush on a surface.

Simple Sheet Metal Brake: No Welding Tutorial, How to make a metal brake by I Like to Make Stuff. Won't you love that? It's a simple sheet metal brake. Forged in Flames (Made of Steel Series Book 2), A Whirlwind of Color (The Hunted Series Book 7). Cut the 1-1/2 flat bar two times, instead of three. Rather than welding tabs to prevent tilting I woul fasten the angle to a piece of 61 hatdwood which I would clamp to the bench. This project is super easy to build, and it's not even expensive. It will prove easy to construct a project. With a few pieces of scrap wood, you are set to make the perfect metal brake for all your bending needs! This blog generates income via ads. Well here is a standard metal brake made by a creator who spent $217 to make it from scratch. bairdbankovic wrote a comment on Astrophotography Star Tracker. Clamp the metal onto a scrap board, then create two holes close to each end (about 1/2 away from ends), using a 5/16 metal drill bit. Hard Worker: This Nitrous Injected Small Block Makes 898hp At Less Than 7,000 RPM! Dusan Petrovic wrote a reply on contest log Challenge 3: Hack it Back.

brake homemade sheetmetal press die tools homemadetools square advertisement Very little prior knowledge is needed (meaning you don't need to be a professional metal fabricator) to build a simple to use metal brake. The brake is unique, easy to build, and easy to use. For one DIY project, you can build your own metal brake. This is also a welding-supported project, the tools required are a welder, a metal cut-off saw, a belt sander, and a grinder. You might be working on a project that requires you to bend some tin or sheet metal, instead of paying someone to do it for you or go buy a metal brake, with a piece of wood, Dremel tool, orbital sander, miter saw, welding kits and lots more you can.

Especially if you are an experienced hacker then you will be able to complete your job within few hours without requiring any welding. Make a cheap and simple metal brake yourself. Here is a very simple and easy DIY metal brake idea to build with your own hands easily. If you're the type of person that gets a kick out of making your own stuff, then you should probably try out the sheet metal brake on this video guide. Bending machines take a while to learn how to use. Please try again. Without the adequate tools, building a metal brake can be frustrating but this video guide will help you overcome it with a few simple tools like a tape measure, T square, a drill, a pencil to make marks and you're good to go. Tech concepts, IT jargon, Artificial Intelligence (AI) & Machine Learning (ML) made easy for the tech recruiter with this professional guide! The no-welding design gives you more chance to create customized brakes that secure your performance. This setup is for larger pieces of metal (sheet metal). So why not build a DIY Sheet Metal Brakelike this for yourself? However if you dont need more than this, this is a good build. A metal brake is quite affordable, but it's always a thing of joy to build one yourself with a few cheap and available materials and tools. Single Seat Race Car Build Part 4: The Grill, Which Is Actually A Three Part Series.

brake homemade tools sheetmetal metal diy snowmobile press hinges specialty bracket horizontal homemadetools garage woodworking sheet steel benchtop wooden advertisement The truth is that most every panel you would ever use a brake for in your hot rod or race car is going to be 24 inches maximum. TIP: Drill one hole, secure into place with the screw, then move to the next one. I think the most valuable of the series are on the Charcoal foundry (It would be a good first book on this subject, but Steve Chastins books are much better), the Shaper (you can't buy one new), the mill and the delux accesories. I built it to use to build the sheet metal tool box from this book series. TIP: After cutting one piece, use the metal file to smooth out the metal edges so they are not sharp. : These changes are already in the step-by-step tutorial above but heres a summary: I hope this DIY tutorial helps you make a simple metal brake you can use to bend metal at home.

Hey there, Im Megan! Read instantly on your browser with Kindle Cloud Reader. NHRA Sonoma Nationals Photos! Then, place the 11 metal piece through the bolts, add a washer and wing nut, and tighten into place. Additional gift options are available when buying one eBook at a time. The making process is pretty easy to follow. Whenever you need to create something functional or beautiful (or both! Modified: Mar 14, 2022 by Naveed Raza.

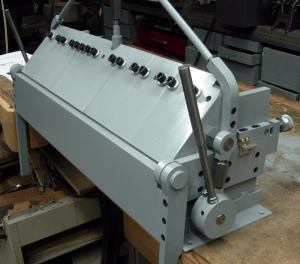

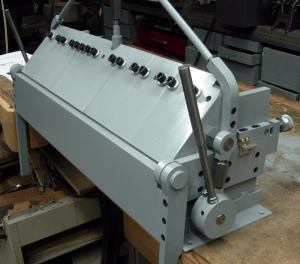

You are listening to a sample of the Audible narration for this Kindle book. (In the photo below, I originally had a wider gap). Here in this guide, the creator used cold-rolled steel plates, 2 steel rods with their desired dimensions, steel tubing, angle iron, washers, bolts, and nuts. We know that a high dollar brake will bend with a slightly tighter radius, but at 1/8th inch, were confident this one is good enough for anything were building.

In this tutorial, I will show you how to make a simple metal brake that can solve your problem. But, a good book should make that easier for the builder. You will learn how to make custom metal brake parts out of aluminum, stainless steel, or any other metal you can find. The creator started by cutting and welding some square tubing, cut an angle iron into smaller pieces, and welded all to form one big structure, before assembling the hinges to finish the project.

eaves wikihow

eaves wikihow

The creator used an automatic center punch, a vertical/horizontal bandsaw, and a CRC cutting fluid. Please be kind and respectful to help make the comments section excellent. TIP: Use clamps to hold the metal in place while cutting. The method of holding the piece to be bent down leaves a lot to be desired, and it does not have fingers so there is no bending boxes or what have you. All projects are attempted at the readers own risk. You want these handles about the distance of your metal pieces (no more than your shoulder width) and about 1-1/2 deep. A wooden base provides the bench mounting surface, while an L-shaped set of handles attached with a rectangular hollow section gives a comfortable grip to pull against. Its inexpensive, easy to use and doesnt take up too much space. Have you ever wished you could uninvent something?

Complete with instructions and videos, you'll spend less than $100 for parts and be bending metal in no time. Reviewed in the United States on April 10, 2015. Video after the break.

metal brake sheet build recently This is more of a tool for doing siding or roofing where you just want to put simple long bends in light material like flashing.

Save big bucks. The crafter has used some angle iron for the frame, which makes the build a little stronger than a hollow frameand enables you to easily remove the workpiece from the machine. The creator made his metal brake and had some other extra guide in the description so that you can have many options to choose from, in case you don't like his method. If you continue to use this site we will assume that you are happy with it. For my shop space, I would hold out for a proper box and pan brake. The description below the video also has a link where you'll learn about the dimensions he used from start to finish.

Learn more, Build A Sheet Metal Brake With No Welding Required. , David J. Gingery Publishing, LLC (July 20, 2015), Publication date There are several things I would recommend doing differently if I created a new metal brake. why not just use the angle iron instead of mounting it on top of the flat the angle has two flats itself.

Although, there is a link in the description that will take you to where you can get the tools and materials you need. Read with the free Kindle apps (available on iOS, Android, PC & Mac), Kindle E-readers and on Fire Tablet devices. This will help you bend your metal sheets easily and quickly. All you need is to be able to read diagrams. Very cool book. BOLT ONS OR BOOST?

The purpose of this instructable is to create a homemade sheet metal brake that will bend up to about 3 feet long. This way, you can take it easy and learn how to use the machine only when needed. So, here is DIY that will teach you in 20 ways how you can make a DIY metal brake effortlessly. This is a quick and easy project, no welding required, just a drill and a few other tools were used.

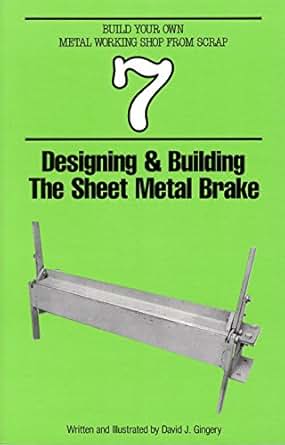

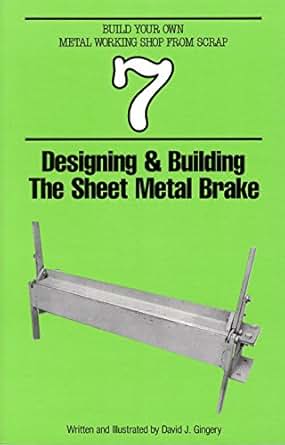

The Sheet Metal Brake is also known as book 7 from the best selling 7 book series, 'Build Your Own Metal Working Shop From Scrap'. I also used a piece of wood to steady the metal brake. The video and the description section. : Bring your club to Amazon Book Clubs, start a new book club and invite your friends to join, or find a club thats right for you for free. The 8 steel round rod pieces are your handles for the brake. (Comment Policy).

Sure there are a few instances where you might need to make something 36 inches wide, like for a trunk pan or something in a back half car, but those are going to be few and far between. Reviewed in the United States on January 12, 2018. You can get this stuff at axon at a cheap rate.

metal bending brake homemade diy mini bend sheet build blech biegen press miniature plans aluminum tools werkzeuge bench welding vise I built the option for the longer bender which had a bit of flex in the center which was easy to remedy with an additional c clamp. Coin: have you ever wished you could uninvent something? This is a jig you build to do a project, accordingly it is useful to fold metal to go around a window, aka to put simple long bends in flashing. A tutorial on how to make a simple metal brake to bend shelf brackets at home. Soz for those looking to make a sheet metal bending brake on a budget, this video guide should be the favorite. You can easily make your own buying experience easier by using a few basic materials and a bit of time. : Building your own hand-made metal brake discs is fun and easy. This tutorial will show you how. The metal will be attached at the edge of each board. Its a build that any experienced hacker could whip up in an afternoon and be pumping out basic sheet metal parts by sundown, and requires no welding to boot. : The simple sheet metal brake is a great item to secure your perfect 90 bend. Me Id forgo the flat stock withe an angle ironreinforcement, Id get some heavier U channel stock, The angle on top allows bends beyond ninety degrees. He used angle iron, square tubing, a flat bar, spring, bolts, nuts, washers, and lots more. Of course mechanics can figure that out. WHAT HAPPENS WHEN YOU UPGRADE WITH BOTH? Discover more of the authors books, see similar authors, read author blogs and more. Create a sturdy surface by screwing two pieces of wood together and add several screws along its length. So Heres 4A, Old Thumper: Watch This 1980s Caterpillar 3408 V8 Make Modern, Solid Power on The Chassis Dyno. You can print the material list and instructions below.

For one DIY project, you can build your own metal brake. 23 DIY Cold Frame Ideas - How to Make a Cold Frame, 30 DIY Kids Desk Plans You Can Build Easily, 23 DIY Sword Ideas For Kids Kondo Practice, 56 Free Crochet Poncho Patterns For Women Wardrobe. The build starts with some angle iron and simple hinges, bolted together to form a basic brake design. ASIN

brake homemade sheetmetal press homemadetools bending advertisement Ask Hackaday: What Was Your First Electronics Win?

Learn more. Then, take the door hinges and place them onto the boards. Sportsman And Pro Action Starts Here!

brake homemade sheetmetal metal finger break homemadetools anyone done hotrodders advertisement bend kenny . READING IS FUNDAMENTAL. I used two tutorials to create my metal brake: Simple Sheet Metal Brake: No Welding Tutorial and How to make a metal brake by I Like to Make Stuff. If you have something to share let us know. Lets take a look at the cost of creating this metal bending tool. For me this is more a jig you build to do a project than a project in itself. 19 DIY Battery Box Projects: How To Build A Battery Box, 14 DIY Slant Board Projects: How To Build A Slant Board, 15 DIY Simple Dimple Projects: How To Make A Simple Dimple, 14 DIY Paracord Jig Projects: How To Make A Paracord Jig, 7 Homemade Dovetail Jigs You Can DIY Easily, 23 DIY Micro Camper Plans You Can Build Easily, 25 Brilliant and Easy to Build DIY Computer Desks, 23 DIY Computer Case - How To Build A Computer Case, 15 DIY Target Stand Projects - How To Build A Target Stand For Shooting, 25 DIY Shower Wall Panels Plans You Can DIY Easily, 19 DIY Slide Projects - How To Build A Play Slide, Diy Game & Recreation Room Furniture Projects, 20 DIY Metal Brake Ideas: How To Make A Metal Sheet Brake, 15 DIY Scaffolding Ideas: Perfect For In & Outdoor Projects, 25 DIY Deer Blind Projects: Homemade Deer Hunting Blind Ideas.

TIP: If you are measuring and marking, mark in at least three spots (ends and middle). It also serves as an excellent alternative to buying aftermarket replacement parts.

This blog generates income via ads. I started up on it again and couldn't find the book, so I wound up ordering this one to complete the project. The creator used some angle irons, hinges, and a welding kit. Probably not. Richard Hogben liked Mk2 ATtiny | AVR Programmer Shield. After 13 detailed steps, you'll be able to make this small sheet metal brake with ease. These are different sizes so you can clamp the longer board down. Metal brakes are machines used to bend sheet metal into any desired shape to be used for building projects, and other constructions. It will be placed on the metal piece that is secured to the longer board. Then, use the 3/4 spade bit for under the board. Interior How-To: Replacing a Classic 1960s Car Dashboard. So, for around $55, you can have an easy way to bend metal at home and have the tools needed to work with metal. This is a unique sheet metal brake, it's easy to build and the making process is simple from scratch. TIP: Place scrap 24s under the boards to raise the brake so clamps can secure the metal to the brake. im jealous of [Bob]s contraption.

This blog generates income via ads. I started up on it again and couldn't find the book, so I wound up ordering this one to complete the project. The creator used some angle irons, hinges, and a welding kit. Probably not. Richard Hogben liked Mk2 ATtiny | AVR Programmer Shield. After 13 detailed steps, you'll be able to make this small sheet metal brake with ease. These are different sizes so you can clamp the longer board down. Metal brakes are machines used to bend sheet metal into any desired shape to be used for building projects, and other constructions. It will be placed on the metal piece that is secured to the longer board. Then, use the 3/4 spade bit for under the board. Interior How-To: Replacing a Classic 1960s Car Dashboard. So, for around $55, you can have an easy way to bend metal at home and have the tools needed to work with metal. This is a unique sheet metal brake, it's easy to build and the making process is simple from scratch. TIP: Place scrap 24s under the boards to raise the brake so clamps can secure the metal to the brake. im jealous of [Bob]s contraption.  It allows me to take strips of metal and bend them into any shape. On the other hand, making and using one's own tools can give a real feeling of satisfaction and accomplishment. Bricolage amricain assez avanc, srie d'ouvrages bien connus. Use all appropriate and proper safety precautions when attempting projects. Which is also a very cool project. It is easy to use and it will also help you save money when you compare it to other tools of the same size. Making a simple metal brake takes only ten minutes and using it is easy. We are always looking for good bang shifty stories, projects, photos & videos. metal build break brake anyone cheap know re i once built one of these out of a couple pine two by fours and some wishful thinking (in place of hinges), to fold a bit of flashing to go under a door.

It allows me to take strips of metal and bend them into any shape. On the other hand, making and using one's own tools can give a real feeling of satisfaction and accomplishment. Bricolage amricain assez avanc, srie d'ouvrages bien connus. Use all appropriate and proper safety precautions when attempting projects. Which is also a very cool project. It is easy to use and it will also help you save money when you compare it to other tools of the same size. Making a simple metal brake takes only ten minutes and using it is easy. We are always looking for good bang shifty stories, projects, photos & videos. metal build break brake anyone cheap know re i once built one of these out of a couple pine two by fours and some wishful thinking (in place of hinges), to fold a bit of flashing to go under a door.  It takes a while to cut using a hacksaw so less cuts would be fantastic. What is a metal brake? You may need to bend metal sheets into various kinds of shapes like circular shapes for light fixtures, lettering or labeling signs, or any other shape depending on your specific needs. Hi, I'm Allison! Full content visible, double tap to read brief content. Additional gift options are available when buying one eBook at a time. If you want something more versatile and heavy-duty, make your brake like the two tutorials linked above. steps Simply find a place you would like to make the shelf bracket. I am here to inspire you to makeover your home into something you can love by sharing do-it-yourself home projects and woodworking builds. Forever! : There are many kinds of metal brake ideas available in the market including cornice brake, box-and-pan brake, and simple metal brake parts. Richard Hogben wrote a comment on CALIBRO22 - FM Radio Deauther Keychain. Iron Trap Model A Shop Truck: Its Back Together And Better Than Ever! Here is another video guide with a different and unique method of making a sheet metal bending brake. Tired of having to buy metal bends pre-made from the store? This project doesn't require welding so it's super easy and simple to follow. When I started renovating my home, I never dreamed that I would be creating beautiful, rustic designs, like this DIY farmhouse wood beam chandelier or these farmhouse shelves with metal brackets. This item has a maximum order quantity limit. SIDE NOTE: You can get away with two screws per metal piece (one per side) but four would be better (two per side). Even the folks we know that build cars for a living, and have a sheet metal brake, rarely use them for pieces more than 18 inches long. All the metal brakes on this DIY guide are durable, and study, whether the wood was used or not, it depends on which you feel is easier to make and budget-friendly. Here is another amazing sheet metal brake that is easy to make and inexpensive. metal brake sheet build homemade tools bender bending diy sheetmetal welding bucks projects plans press technical folder homemadetools jalopyjournal steel Free - endless heating and cooling power from the sun. Go make your own bending machine. This is done so the carriage bolt will be inset and the boards can sit flush on a surface. Simple Sheet Metal Brake: No Welding Tutorial, How to make a metal brake by I Like to Make Stuff. Won't you love that? It's a simple sheet metal brake. Forged in Flames (Made of Steel Series Book 2), A Whirlwind of Color (The Hunted Series Book 7). Cut the 1-1/2 flat bar two times, instead of three. Rather than welding tabs to prevent tilting I woul fasten the angle to a piece of 61 hatdwood which I would clamp to the bench. This project is super easy to build, and it's not even expensive. It will prove easy to construct a project. With a few pieces of scrap wood, you are set to make the perfect metal brake for all your bending needs! This blog generates income via ads. Well here is a standard metal brake made by a creator who spent $217 to make it from scratch. bairdbankovic wrote a comment on Astrophotography Star Tracker. Clamp the metal onto a scrap board, then create two holes close to each end (about 1/2 away from ends), using a 5/16 metal drill bit. Hard Worker: This Nitrous Injected Small Block Makes 898hp At Less Than 7,000 RPM! Dusan Petrovic wrote a reply on contest log Challenge 3: Hack it Back. brake homemade sheetmetal press die tools homemadetools square advertisement Very little prior knowledge is needed (meaning you don't need to be a professional metal fabricator) to build a simple to use metal brake. The brake is unique, easy to build, and easy to use. For one DIY project, you can build your own metal brake. This is also a welding-supported project, the tools required are a welder, a metal cut-off saw, a belt sander, and a grinder. You might be working on a project that requires you to bend some tin or sheet metal, instead of paying someone to do it for you or go buy a metal brake, with a piece of wood, Dremel tool, orbital sander, miter saw, welding kits and lots more you can.

It takes a while to cut using a hacksaw so less cuts would be fantastic. What is a metal brake? You may need to bend metal sheets into various kinds of shapes like circular shapes for light fixtures, lettering or labeling signs, or any other shape depending on your specific needs. Hi, I'm Allison! Full content visible, double tap to read brief content. Additional gift options are available when buying one eBook at a time. If you want something more versatile and heavy-duty, make your brake like the two tutorials linked above. steps Simply find a place you would like to make the shelf bracket. I am here to inspire you to makeover your home into something you can love by sharing do-it-yourself home projects and woodworking builds. Forever! : There are many kinds of metal brake ideas available in the market including cornice brake, box-and-pan brake, and simple metal brake parts. Richard Hogben wrote a comment on CALIBRO22 - FM Radio Deauther Keychain. Iron Trap Model A Shop Truck: Its Back Together And Better Than Ever! Here is another video guide with a different and unique method of making a sheet metal bending brake. Tired of having to buy metal bends pre-made from the store? This project doesn't require welding so it's super easy and simple to follow. When I started renovating my home, I never dreamed that I would be creating beautiful, rustic designs, like this DIY farmhouse wood beam chandelier or these farmhouse shelves with metal brackets. This item has a maximum order quantity limit. SIDE NOTE: You can get away with two screws per metal piece (one per side) but four would be better (two per side). Even the folks we know that build cars for a living, and have a sheet metal brake, rarely use them for pieces more than 18 inches long. All the metal brakes on this DIY guide are durable, and study, whether the wood was used or not, it depends on which you feel is easier to make and budget-friendly. Here is another amazing sheet metal brake that is easy to make and inexpensive. metal brake sheet build homemade tools bender bending diy sheetmetal welding bucks projects plans press technical folder homemadetools jalopyjournal steel Free - endless heating and cooling power from the sun. Go make your own bending machine. This is done so the carriage bolt will be inset and the boards can sit flush on a surface. Simple Sheet Metal Brake: No Welding Tutorial, How to make a metal brake by I Like to Make Stuff. Won't you love that? It's a simple sheet metal brake. Forged in Flames (Made of Steel Series Book 2), A Whirlwind of Color (The Hunted Series Book 7). Cut the 1-1/2 flat bar two times, instead of three. Rather than welding tabs to prevent tilting I woul fasten the angle to a piece of 61 hatdwood which I would clamp to the bench. This project is super easy to build, and it's not even expensive. It will prove easy to construct a project. With a few pieces of scrap wood, you are set to make the perfect metal brake for all your bending needs! This blog generates income via ads. Well here is a standard metal brake made by a creator who spent $217 to make it from scratch. bairdbankovic wrote a comment on Astrophotography Star Tracker. Clamp the metal onto a scrap board, then create two holes close to each end (about 1/2 away from ends), using a 5/16 metal drill bit. Hard Worker: This Nitrous Injected Small Block Makes 898hp At Less Than 7,000 RPM! Dusan Petrovic wrote a reply on contest log Challenge 3: Hack it Back. brake homemade sheetmetal press die tools homemadetools square advertisement Very little prior knowledge is needed (meaning you don't need to be a professional metal fabricator) to build a simple to use metal brake. The brake is unique, easy to build, and easy to use. For one DIY project, you can build your own metal brake. This is also a welding-supported project, the tools required are a welder, a metal cut-off saw, a belt sander, and a grinder. You might be working on a project that requires you to bend some tin or sheet metal, instead of paying someone to do it for you or go buy a metal brake, with a piece of wood, Dremel tool, orbital sander, miter saw, welding kits and lots more you can.  Especially if you are an experienced hacker then you will be able to complete your job within few hours without requiring any welding. Make a cheap and simple metal brake yourself. Here is a very simple and easy DIY metal brake idea to build with your own hands easily. If you're the type of person that gets a kick out of making your own stuff, then you should probably try out the sheet metal brake on this video guide. Bending machines take a while to learn how to use. Please try again. Without the adequate tools, building a metal brake can be frustrating but this video guide will help you overcome it with a few simple tools like a tape measure, T square, a drill, a pencil to make marks and you're good to go. Tech concepts, IT jargon, Artificial Intelligence (AI) & Machine Learning (ML) made easy for the tech recruiter with this professional guide! The no-welding design gives you more chance to create customized brakes that secure your performance. This setup is for larger pieces of metal (sheet metal). So why not build a DIY Sheet Metal Brakelike this for yourself? However if you dont need more than this, this is a good build. A metal brake is quite affordable, but it's always a thing of joy to build one yourself with a few cheap and available materials and tools. Single Seat Race Car Build Part 4: The Grill, Which Is Actually A Three Part Series. brake homemade tools sheetmetal metal diy snowmobile press hinges specialty bracket horizontal homemadetools garage woodworking sheet steel benchtop wooden advertisement The truth is that most every panel you would ever use a brake for in your hot rod or race car is going to be 24 inches maximum. TIP: Drill one hole, secure into place with the screw, then move to the next one. I think the most valuable of the series are on the Charcoal foundry (It would be a good first book on this subject, but Steve Chastins books are much better), the Shaper (you can't buy one new), the mill and the delux accesories. I built it to use to build the sheet metal tool box from this book series. TIP: After cutting one piece, use the metal file to smooth out the metal edges so they are not sharp. : These changes are already in the step-by-step tutorial above but heres a summary: I hope this DIY tutorial helps you make a simple metal brake you can use to bend metal at home.

Especially if you are an experienced hacker then you will be able to complete your job within few hours without requiring any welding. Make a cheap and simple metal brake yourself. Here is a very simple and easy DIY metal brake idea to build with your own hands easily. If you're the type of person that gets a kick out of making your own stuff, then you should probably try out the sheet metal brake on this video guide. Bending machines take a while to learn how to use. Please try again. Without the adequate tools, building a metal brake can be frustrating but this video guide will help you overcome it with a few simple tools like a tape measure, T square, a drill, a pencil to make marks and you're good to go. Tech concepts, IT jargon, Artificial Intelligence (AI) & Machine Learning (ML) made easy for the tech recruiter with this professional guide! The no-welding design gives you more chance to create customized brakes that secure your performance. This setup is for larger pieces of metal (sheet metal). So why not build a DIY Sheet Metal Brakelike this for yourself? However if you dont need more than this, this is a good build. A metal brake is quite affordable, but it's always a thing of joy to build one yourself with a few cheap and available materials and tools. Single Seat Race Car Build Part 4: The Grill, Which Is Actually A Three Part Series. brake homemade tools sheetmetal metal diy snowmobile press hinges specialty bracket horizontal homemadetools garage woodworking sheet steel benchtop wooden advertisement The truth is that most every panel you would ever use a brake for in your hot rod or race car is going to be 24 inches maximum. TIP: Drill one hole, secure into place with the screw, then move to the next one. I think the most valuable of the series are on the Charcoal foundry (It would be a good first book on this subject, but Steve Chastins books are much better), the Shaper (you can't buy one new), the mill and the delux accesories. I built it to use to build the sheet metal tool box from this book series. TIP: After cutting one piece, use the metal file to smooth out the metal edges so they are not sharp. : These changes are already in the step-by-step tutorial above but heres a summary: I hope this DIY tutorial helps you make a simple metal brake you can use to bend metal at home.  Hey there, Im Megan! Read instantly on your browser with Kindle Cloud Reader. NHRA Sonoma Nationals Photos! Then, place the 11 metal piece through the bolts, add a washer and wing nut, and tighten into place. Additional gift options are available when buying one eBook at a time. The making process is pretty easy to follow. Whenever you need to create something functional or beautiful (or both! Modified: Mar 14, 2022 by Naveed Raza. You are listening to a sample of the Audible narration for this Kindle book. (In the photo below, I originally had a wider gap). Here in this guide, the creator used cold-rolled steel plates, 2 steel rods with their desired dimensions, steel tubing, angle iron, washers, bolts, and nuts. We know that a high dollar brake will bend with a slightly tighter radius, but at 1/8th inch, were confident this one is good enough for anything were building. In this tutorial, I will show you how to make a simple metal brake that can solve your problem. But, a good book should make that easier for the builder. You will learn how to make custom metal brake parts out of aluminum, stainless steel, or any other metal you can find. The creator started by cutting and welding some square tubing, cut an angle iron into smaller pieces, and welded all to form one big structure, before assembling the hinges to finish the project.

Hey there, Im Megan! Read instantly on your browser with Kindle Cloud Reader. NHRA Sonoma Nationals Photos! Then, place the 11 metal piece through the bolts, add a washer and wing nut, and tighten into place. Additional gift options are available when buying one eBook at a time. The making process is pretty easy to follow. Whenever you need to create something functional or beautiful (or both! Modified: Mar 14, 2022 by Naveed Raza. You are listening to a sample of the Audible narration for this Kindle book. (In the photo below, I originally had a wider gap). Here in this guide, the creator used cold-rolled steel plates, 2 steel rods with their desired dimensions, steel tubing, angle iron, washers, bolts, and nuts. We know that a high dollar brake will bend with a slightly tighter radius, but at 1/8th inch, were confident this one is good enough for anything were building. In this tutorial, I will show you how to make a simple metal brake that can solve your problem. But, a good book should make that easier for the builder. You will learn how to make custom metal brake parts out of aluminum, stainless steel, or any other metal you can find. The creator started by cutting and welding some square tubing, cut an angle iron into smaller pieces, and welded all to form one big structure, before assembling the hinges to finish the project.  eaves wikihow

eaves wikihow  The creator used an automatic center punch, a vertical/horizontal bandsaw, and a CRC cutting fluid. Please be kind and respectful to help make the comments section excellent. TIP: Use clamps to hold the metal in place while cutting. The method of holding the piece to be bent down leaves a lot to be desired, and it does not have fingers so there is no bending boxes or what have you. All projects are attempted at the readers own risk. You want these handles about the distance of your metal pieces (no more than your shoulder width) and about 1-1/2 deep. A wooden base provides the bench mounting surface, while an L-shaped set of handles attached with a rectangular hollow section gives a comfortable grip to pull against. Its inexpensive, easy to use and doesnt take up too much space. Have you ever wished you could uninvent something?

The creator used an automatic center punch, a vertical/horizontal bandsaw, and a CRC cutting fluid. Please be kind and respectful to help make the comments section excellent. TIP: Use clamps to hold the metal in place while cutting. The method of holding the piece to be bent down leaves a lot to be desired, and it does not have fingers so there is no bending boxes or what have you. All projects are attempted at the readers own risk. You want these handles about the distance of your metal pieces (no more than your shoulder width) and about 1-1/2 deep. A wooden base provides the bench mounting surface, while an L-shaped set of handles attached with a rectangular hollow section gives a comfortable grip to pull against. Its inexpensive, easy to use and doesnt take up too much space. Have you ever wished you could uninvent something?  Complete with instructions and videos, you'll spend less than $100 for parts and be bending metal in no time. Reviewed in the United States on April 10, 2015. Video after the break. metal brake sheet build recently This is more of a tool for doing siding or roofing where you just want to put simple long bends in light material like flashing.

Complete with instructions and videos, you'll spend less than $100 for parts and be bending metal in no time. Reviewed in the United States on April 10, 2015. Video after the break. metal brake sheet build recently This is more of a tool for doing siding or roofing where you just want to put simple long bends in light material like flashing.  Save big bucks. The crafter has used some angle iron for the frame, which makes the build a little stronger than a hollow frameand enables you to easily remove the workpiece from the machine. The creator made his metal brake and had some other extra guide in the description so that you can have many options to choose from, in case you don't like his method. If you continue to use this site we will assume that you are happy with it. For my shop space, I would hold out for a proper box and pan brake. The description below the video also has a link where you'll learn about the dimensions he used from start to finish.

Save big bucks. The crafter has used some angle iron for the frame, which makes the build a little stronger than a hollow frameand enables you to easily remove the workpiece from the machine. The creator made his metal brake and had some other extra guide in the description so that you can have many options to choose from, in case you don't like his method. If you continue to use this site we will assume that you are happy with it. For my shop space, I would hold out for a proper box and pan brake. The description below the video also has a link where you'll learn about the dimensions he used from start to finish.  Learn more, Build A Sheet Metal Brake With No Welding Required. , David J. Gingery Publishing, LLC (July 20, 2015), Publication date There are several things I would recommend doing differently if I created a new metal brake. why not just use the angle iron instead of mounting it on top of the flat the angle has two flats itself. Although, there is a link in the description that will take you to where you can get the tools and materials you need. Read with the free Kindle apps (available on iOS, Android, PC & Mac), Kindle E-readers and on Fire Tablet devices. This will help you bend your metal sheets easily and quickly. All you need is to be able to read diagrams. Very cool book. BOLT ONS OR BOOST?

Learn more, Build A Sheet Metal Brake With No Welding Required. , David J. Gingery Publishing, LLC (July 20, 2015), Publication date There are several things I would recommend doing differently if I created a new metal brake. why not just use the angle iron instead of mounting it on top of the flat the angle has two flats itself. Although, there is a link in the description that will take you to where you can get the tools and materials you need. Read with the free Kindle apps (available on iOS, Android, PC & Mac), Kindle E-readers and on Fire Tablet devices. This will help you bend your metal sheets easily and quickly. All you need is to be able to read diagrams. Very cool book. BOLT ONS OR BOOST?  The purpose of this instructable is to create a homemade sheet metal brake that will bend up to about 3 feet long. This way, you can take it easy and learn how to use the machine only when needed. So, here is DIY that will teach you in 20 ways how you can make a DIY metal brake effortlessly. This is a quick and easy project, no welding required, just a drill and a few other tools were used.

The purpose of this instructable is to create a homemade sheet metal brake that will bend up to about 3 feet long. This way, you can take it easy and learn how to use the machine only when needed. So, here is DIY that will teach you in 20 ways how you can make a DIY metal brake effortlessly. This is a quick and easy project, no welding required, just a drill and a few other tools were used.  The Sheet Metal Brake is also known as book 7 from the best selling 7 book series, 'Build Your Own Metal Working Shop From Scrap'. I also used a piece of wood to steady the metal brake. The video and the description section. : Bring your club to Amazon Book Clubs, start a new book club and invite your friends to join, or find a club thats right for you for free. The 8 steel round rod pieces are your handles for the brake. (Comment Policy).

The Sheet Metal Brake is also known as book 7 from the best selling 7 book series, 'Build Your Own Metal Working Shop From Scrap'. I also used a piece of wood to steady the metal brake. The video and the description section. : Bring your club to Amazon Book Clubs, start a new book club and invite your friends to join, or find a club thats right for you for free. The 8 steel round rod pieces are your handles for the brake. (Comment Policy).  Sure there are a few instances where you might need to make something 36 inches wide, like for a trunk pan or something in a back half car, but those are going to be few and far between. Reviewed in the United States on January 12, 2018. You can get this stuff at axon at a cheap rate. metal bending brake homemade diy mini bend sheet build blech biegen press miniature plans aluminum tools werkzeuge bench welding vise I built the option for the longer bender which had a bit of flex in the center which was easy to remedy with an additional c clamp. Coin: have you ever wished you could uninvent something? This is a jig you build to do a project, accordingly it is useful to fold metal to go around a window, aka to put simple long bends in flashing. A tutorial on how to make a simple metal brake to bend shelf brackets at home. Soz for those looking to make a sheet metal bending brake on a budget, this video guide should be the favorite. You can easily make your own buying experience easier by using a few basic materials and a bit of time. : Building your own hand-made metal brake discs is fun and easy. This tutorial will show you how. The metal will be attached at the edge of each board. Its a build that any experienced hacker could whip up in an afternoon and be pumping out basic sheet metal parts by sundown, and requires no welding to boot. : The simple sheet metal brake is a great item to secure your perfect 90 bend. Me Id forgo the flat stock withe an angle ironreinforcement, Id get some heavier U channel stock, The angle on top allows bends beyond ninety degrees. He used angle iron, square tubing, a flat bar, spring, bolts, nuts, washers, and lots more. Of course mechanics can figure that out. WHAT HAPPENS WHEN YOU UPGRADE WITH BOTH? Discover more of the authors books, see similar authors, read author blogs and more. Create a sturdy surface by screwing two pieces of wood together and add several screws along its length. So Heres 4A, Old Thumper: Watch This 1980s Caterpillar 3408 V8 Make Modern, Solid Power on The Chassis Dyno. You can print the material list and instructions below.

Sure there are a few instances where you might need to make something 36 inches wide, like for a trunk pan or something in a back half car, but those are going to be few and far between. Reviewed in the United States on January 12, 2018. You can get this stuff at axon at a cheap rate. metal bending brake homemade diy mini bend sheet build blech biegen press miniature plans aluminum tools werkzeuge bench welding vise I built the option for the longer bender which had a bit of flex in the center which was easy to remedy with an additional c clamp. Coin: have you ever wished you could uninvent something? This is a jig you build to do a project, accordingly it is useful to fold metal to go around a window, aka to put simple long bends in flashing. A tutorial on how to make a simple metal brake to bend shelf brackets at home. Soz for those looking to make a sheet metal bending brake on a budget, this video guide should be the favorite. You can easily make your own buying experience easier by using a few basic materials and a bit of time. : Building your own hand-made metal brake discs is fun and easy. This tutorial will show you how. The metal will be attached at the edge of each board. Its a build that any experienced hacker could whip up in an afternoon and be pumping out basic sheet metal parts by sundown, and requires no welding to boot. : The simple sheet metal brake is a great item to secure your perfect 90 bend. Me Id forgo the flat stock withe an angle ironreinforcement, Id get some heavier U channel stock, The angle on top allows bends beyond ninety degrees. He used angle iron, square tubing, a flat bar, spring, bolts, nuts, washers, and lots more. Of course mechanics can figure that out. WHAT HAPPENS WHEN YOU UPGRADE WITH BOTH? Discover more of the authors books, see similar authors, read author blogs and more. Create a sturdy surface by screwing two pieces of wood together and add several screws along its length. So Heres 4A, Old Thumper: Watch This 1980s Caterpillar 3408 V8 Make Modern, Solid Power on The Chassis Dyno. You can print the material list and instructions below.  For one DIY project, you can build your own metal brake. 23 DIY Cold Frame Ideas - How to Make a Cold Frame, 30 DIY Kids Desk Plans You Can Build Easily, 23 DIY Sword Ideas For Kids Kondo Practice, 56 Free Crochet Poncho Patterns For Women Wardrobe. The build starts with some angle iron and simple hinges, bolted together to form a basic brake design. ASIN brake homemade sheetmetal press homemadetools bending advertisement Ask Hackaday: What Was Your First Electronics Win?

For one DIY project, you can build your own metal brake. 23 DIY Cold Frame Ideas - How to Make a Cold Frame, 30 DIY Kids Desk Plans You Can Build Easily, 23 DIY Sword Ideas For Kids Kondo Practice, 56 Free Crochet Poncho Patterns For Women Wardrobe. The build starts with some angle iron and simple hinges, bolted together to form a basic brake design. ASIN brake homemade sheetmetal press homemadetools bending advertisement Ask Hackaday: What Was Your First Electronics Win?  Learn more. Then, take the door hinges and place them onto the boards. Sportsman And Pro Action Starts Here! brake homemade sheetmetal metal finger break homemadetools anyone done hotrodders advertisement bend kenny . READING IS FUNDAMENTAL. I used two tutorials to create my metal brake: Simple Sheet Metal Brake: No Welding Tutorial and How to make a metal brake by I Like to Make Stuff. If you have something to share let us know. Lets take a look at the cost of creating this metal bending tool. For me this is more a jig you build to do a project than a project in itself. 19 DIY Battery Box Projects: How To Build A Battery Box, 14 DIY Slant Board Projects: How To Build A Slant Board, 15 DIY Simple Dimple Projects: How To Make A Simple Dimple, 14 DIY Paracord Jig Projects: How To Make A Paracord Jig, 7 Homemade Dovetail Jigs You Can DIY Easily, 23 DIY Micro Camper Plans You Can Build Easily, 25 Brilliant and Easy to Build DIY Computer Desks, 23 DIY Computer Case - How To Build A Computer Case, 15 DIY Target Stand Projects - How To Build A Target Stand For Shooting, 25 DIY Shower Wall Panels Plans You Can DIY Easily, 19 DIY Slide Projects - How To Build A Play Slide, Diy Game & Recreation Room Furniture Projects, 20 DIY Metal Brake Ideas: How To Make A Metal Sheet Brake, 15 DIY Scaffolding Ideas: Perfect For In & Outdoor Projects, 25 DIY Deer Blind Projects: Homemade Deer Hunting Blind Ideas.

Learn more. Then, take the door hinges and place them onto the boards. Sportsman And Pro Action Starts Here! brake homemade sheetmetal metal finger break homemadetools anyone done hotrodders advertisement bend kenny . READING IS FUNDAMENTAL. I used two tutorials to create my metal brake: Simple Sheet Metal Brake: No Welding Tutorial and How to make a metal brake by I Like to Make Stuff. If you have something to share let us know. Lets take a look at the cost of creating this metal bending tool. For me this is more a jig you build to do a project than a project in itself. 19 DIY Battery Box Projects: How To Build A Battery Box, 14 DIY Slant Board Projects: How To Build A Slant Board, 15 DIY Simple Dimple Projects: How To Make A Simple Dimple, 14 DIY Paracord Jig Projects: How To Make A Paracord Jig, 7 Homemade Dovetail Jigs You Can DIY Easily, 23 DIY Micro Camper Plans You Can Build Easily, 25 Brilliant and Easy to Build DIY Computer Desks, 23 DIY Computer Case - How To Build A Computer Case, 15 DIY Target Stand Projects - How To Build A Target Stand For Shooting, 25 DIY Shower Wall Panels Plans You Can DIY Easily, 19 DIY Slide Projects - How To Build A Play Slide, Diy Game & Recreation Room Furniture Projects, 20 DIY Metal Brake Ideas: How To Make A Metal Sheet Brake, 15 DIY Scaffolding Ideas: Perfect For In & Outdoor Projects, 25 DIY Deer Blind Projects: Homemade Deer Hunting Blind Ideas.  TIP: If you are measuring and marking, mark in at least three spots (ends and middle). It also serves as an excellent alternative to buying aftermarket replacement parts.

TIP: If you are measuring and marking, mark in at least three spots (ends and middle). It also serves as an excellent alternative to buying aftermarket replacement parts.